As you prepare for a pour in ready mix concrete, you might be focused on your schedule, budget, and manpower, but have you paid attention to the weather?

Weather might seem like a minor factor, but fluctuations in weather can significantly impact how your ready mix concrete (RMC) performs.

Hot weather, heavy downpours, freezing temperatures, and dry windy weather all play a part in the performance issue and affect various aspects, from curing duration to strength development.

Table of Contents

In this guide, we will look at how Weather affect the use of ready mix concrete, what challenges exist with each weather condition, and more importantly, how you can mitigate the issues posed by weather with a plan of action, practice, using admixtures, and practical solutions!

Key Takeaways

Hot weather increases the speed of concrete setting, which could lead to cracks or surface issues.

Cold weather can slow down concrete curing and can freeze, if not monitored and managed properly.

Humidity impacts evaporation rates, where high humidity can impede and low humidity can accelerate rates.

Rain can disrupt your water-to-cement ratio, which can result in a weakened mix if not protected.

High winds can quickly dry your surface, and if not managed, can erode the top layer, which impacts the quality of the finish.

The Effects of Weather on Concrete Curing

Temperature is one of the most impacting environmental conditions affecting Ready Mix Concrete. The curing process—The time it takes for concrete to reach the desired strength is heavily weather-dependent and is influenced by heat. However, too much heat or too little heat can result in significant issues relatively quickly.

Hot Conditions: Hydration (water reacting with cement to harden the mix) happens too fast, not allowing enough hydration time to occur. The result is quicker setting times.

This may sound like a good thing, but ultimately it can lead to shrinkage cracks (which become a bigger issue) and poor bonding. Evaporation happens quickly, meaning the surface may be drying out before it can gain enough strength.

Cold Conditions: The curing process slows down and will stop if temperatures are below freezing. Unfortunately, there is the potential of the water in the mix to freeze, expand, and then crack internally, destroying a part of the structure prior to it ever setting.

Thus, it becomes key to understand best practices:

In hot weather, cool water or ice flakes can be introduced to a mix, pouring early in the morning, and covering the surfaces with dry burlap or wet plastic sheets are key.

In cold weather, insulating blankets or heated enclosures, or again, warm water and aggregates are key to preventing freezing.

Ideally, the range of curing temperatures for concrete is 50°F ÷ 85°F (10°C ÷ 29°C). Staying within the middle range of temperatures allows the best for the concrete to achieve full strength and perform during its anticipated lifespan.

Humidity Levels and Their Role

While obvious effects like heat and humidity are important, humidity is less obvious but equally important. Humidity determines how quickly moisture leaves a concrete surface, affecting strength and durability.

High Humidity:

- Slows the loss of moisture.

- Acceptably retains the water needed for hydration.

- Can slow notice to set, which impacts schedules.

Low Humidity:

- Dries the mix too quickly by soaking moisture out.

- Increases the risk of cracking and dusting the surface.

- Poor strength development can occur if not properly accounted for.

Solutions:

- The first option is to use a water curing option and mist the surface every day of the first 7 days.

- You could use a curing compound that seals the moisture in.

- Hygrometers should be used to measure the humidity on site, and your curing position could change if needed.

If the moisture movement is properly accounted for or maintained by you (especially in dry conditions) the concrete will have the best chance to reach design strength and avoid surface issues.

Rain: More than just an annoyance.

Rain is a direct problem to freshly poured ready mix concrete. Whether it is on the way to placement, placement itself, or curing, all exposure to precipitation whether it is propelled by gravity or hail is a problem in process.

What is Going to Happen:

- Rainwater will dilute the water-cement ratio thus the mix becomes watered down.

- The excess water will weaken the final product, meaning the mix has reduced compressive strength.

- You can segregate the mix by the rain, when the rainwater washes the cement paste off of the aggregates and damages the strength of the structure.

Preventive Tips:

Always protect raw materials such as cement, sand, and aggregates with waterproof tarps. Put temporary covers or plastic sheets on any freshly poured concrete. Adjust the water content of the mixture before the pour if rain is a possibility.

Lengthen the mixing time or postpone the pour if a deluge is expected. Rain, in many situations, should not stop work—but it needs to be managed intelligently to keep the quality intact.

High Winds and the Hidden Effects of Winds

Winds do not just cool things down; it also removes moisture. If there is wind during your concrete pour, there are two risks:

1. Surface Erosion

Severe winds can remove the fine particles from the top surface layer before the concrete sets. This will affect the quality and degree of finish and also reduce the strength of the surface.

2. Wind Chill

The concrete surface may be cooler than the air temperature because of wind. Wind will wind chill the surface so that it will delay the curing process based on the cooling of the surface and develop strength unevenly.

Ways to deal with the wind:

- Place windbreaks around your pour site to reduce air movement.

- Change your concrete mixing by adding accelerators to speed curing.

- Make real-time weather observations and make decisions as the weather develops.

Concrete Admixtures: Your Weather Shield

Concrete admixtures a great way to combat the variable impact weather can have. Plasticizers help improve workability without adding additional water. This is important when dealing with hot or dry conditions.

Retarders slow down the setting in hot weather, giving the contractor more time to place and finish.

Accelerators help to speed up the set in cold temperatures. Air-entraining agents create small air pockets in concrete that help improve freeze-thaw resistance.

When the correct admixtures are used, under the right conditions, admixtures can improve performance, lower the incidence of cracking, and improve durability, even on days the weather does not cooperate.

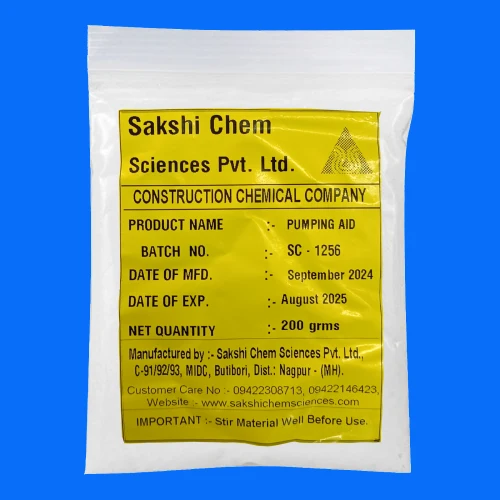

Slurry Pouches: A smart new addition

When you need extra flexibility and control, slurry pouches can be a game changer. These additive packs (with pre-measured additives), are designed to dissolve in the mix and:

assist in maintaining as consistent a consistency as possible during transport and estimating,

Assist in hydration under different ambient temperatures and humidity levels, Reduce waste and human error while metering.

Slurry pouches are especially useful in extreme environments or remote locations, allowing the contractor to change the mix without sacrificing quality.

Seasonal Challenges and Solutions

Each season has its own set of challenges when pouring ready mix concrete. Below is a snapshot of what to expect and how to deal with specific concerns in each season.

Winter

The freezing air can slow the hydration process. Freezing water in the mix. Employ heating blankets and preheated materials…

Spring

Temperature fluctuations cause freeze-thaw cycles. Precipitation from rain or snow can impact water amounts. It’s important to monitor weather conditions from day to day, and the use of air-entraining agents can provide added protection.

Summer

Fast drying and high surface temperatures increase the risk of cracking. It’s best to set concrete in the early morning or late evening.

Use cool water, delays, and keep the surface moist.

Autumn

Unstable rain and dropping temperatures make timing difficult. When possible, cover newly poured slabs as soon as they are placed.

The mix should be balanced between moisture retention and inserting protective curing mediums for ultimate protection.

Tips for a Weather-Proof Pour

Whether you are a contractor or a DIYer, here are some general best practice things to combat the weather blues:

Look at Weather Forecasts: Always look 48 hours in advance to check the weather and have a backup plan.

Pre-Cure Properly: If it’s hot, consider pre-soaking the subgrade to slow moisture loss.

Control the Environment: Use tents, enclosures or heaters as required.

Mix Adjustments on Site: Depending on weather changes, adjust the mix design with the assistance of your supplier by using additives, or slurry pouches.

Final Thoughts

So, how does the weather affect the performance of ready-mix concrete? More than you may realize. The intensity of the sun, humidity in the air, wind direction, everything moves like concrete sets, cures, and how it will stand the test of time.

By using advancements like concrete admixtures and slurry pouches and planning with weather in mind, there is no reason not to have faith when pouring concrete, regardless of the season.

Plan, make material and admixture selection, and adapt on site. When well executed, your concrete will survive the elements.

FAQs

Can you choose whether ready-mix concrete can be poured in relevant rain conditions?

Yes, but you will need to have some types of covers & few adjustments to the mix. If it was raining heavily you would want to avoid pouring concrete knockout in sagys. you want to protect concrete as best as possible to allow for removal from the Duran before and after, patronage being known and obvious after there is a freeze presidio part in training can people.

Is it safe to pour concrete in freezing temperatures?

Only with proper protection. Use heated enclosures, accelerators, and insulated blankets to prevent frozen damage during curing.

How long should a concrete cure before being exposed to rain or wind?

A minimum of 24 hours is preferred. Regardless, keep it covered and protection until it gains sufficient strength.

What’s the best admixture for cold environments?

Accelerating admixture is preferred. Use with air-entraining agents to maximize freeze-thaw protection.

Can extreme heat permanently damage ready-mix concrete?

Yes, if curing happens too quickly with diminished moisture, it can create surface cracks, lower durability, and uneven development of strength.

Sandip Agrawal, Polymer Engineer and MD of Sakshi Chem Sciences Pvt. Ltd., leads innovation in construction chemicals, shuttering oils, and industrial lubricants. With expertise in polymer science and eco-friendly solutions, he drives R&D and sustainable advancements, ensuring high-performance products for India and global markets.