Although concrete is often regarded as strong and durable, it is highly susceptible to environmental conditions during the early stages of pouring and curing.

When pouring concrete in cold weather, careful planning, material selection, and execution are essential to minimize the risk of serious structural problems later on.

Table of Contents

As the temperature decreases, the rate at which the cement in concrete hydrates decreases significantly. If the concrete is not poured and cured adequately in cold weather, a reduction in strength may occur as well as an increased risk of surface defects, cracking, and permanent damage from frost.

By understanding the risks and implementing the necessary precautions, one can ensure that concrete will meet performance expectations, even in inclement weather conditions.

What are the Risks of Pouring Concrete in Cold Weather?

Concrete gains compressive strength over time due to the amount of time the cement has been in contact with water and because of the rate at which the cement hydrates through a chemical reaction.

The rate at which this chemical reaction occurs is very sensitive to temperature. When the temperature drops close to freezing, the rate at which the cement hydrates will dramatically decrease.

If the water in freshly poured concrete freezes before sufficient hydration has taken place, it will expand when frozen, causing internal stresses.

These internal stresses can create:

- Microcracking in the concrete matrix.

- Surface Scaling and Dusting.

- Reduced Compressive Strength.

- Long-term Durability problems.

In severe instances, concrete that has been subjected to early-age freezing may never achieve its intended design compressive strength.

That is why pouring concrete in cold weather without proper precautions is considered one of the most critical risks in construction.

What Is Considered Cold Weather for Concrete Pouring?

Cold weather concreting conditions typically apply when:

- The ambient temperature falls below 5°C for several consecutive days.

- Night-time temperatures approach or fall below 0°C.

- There is a risk of frost during the first few days after pouring.

Under these conditions, special measures must be implemented from batching to curing.

Key Challenges During Cold Weather Concreting

1. Slow Setting and Strength Gain

Low temperatures delay initial and final setting times, slowing down construction schedules and increasing exposure to environmental risks.

2. Frost Damage

Irreparable deterioration occurs when concrete freezes prior to obtaining adequate early strength, typically at approximately 3.5 MPa.

3. A Decrease in Workability

Colder weather increases the viscosity of concrete, thus making it more challenging to distribute, compact, and pump, particularly in complex pours.

4. Thermal Cracking

The disparity between the temperatures of both the surface and core of a concrete member creates thermal stresses; these thermal stresses will eventually create cracks in the concrete member’s surface.

Cold-Weather Preparations Before the Placement of Concrete

Planning occurs long before the actual delivery of the concrete to the job site.

Control the Temperature of the Aggregate

Aggregate must be free from ice, snow, and frost.

Water used for mixing may require heating.

Cement must be stored in a dry, warm, and insulated location.

The objective is to ensure the temperature of the fresh concrete is warm enough to allow adequate bonding through hydration.

Adjustments to Concrete Mixes for the Cold Weather

Optimized Concrete Mix Design

Cold-weather concrete mixes typically consist of:

- A Lower Water-to-Cement Ratio.

- Higher Cement Content for Faster Development of Heat.

- Admixtures that have been specifically selected to Improve Early Strength.

Use of Accelerating Admixtures

Accelerating admixtures can significantly increase the rate of setting and the early development of compressive strengths without negatively impacting durability.

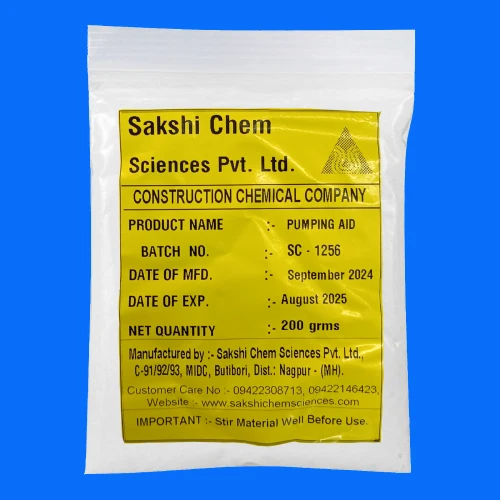

A Pumping Aid is particularly useful in cold weather because it increases the flow of concrete through the piping, reduces resistance in the pipeline, and allows for consistent pumping of the concrete even if the low temperature causes the concrete to become stiffer.

Role of Pumping Aid in Cold Weather Concreting

In cold weather, pumping concrete becomes more challenging due to increased viscosity and reduced lubrication inside pipelines. A Pumping Aid enhances the rheology of concrete, ensuring smooth and continuous placement.

Benefits include:

- Improved pumpability at low temperatures.

- Reduced risk of pipeline blockages.

- Uniform flow without segregation.

- Better compaction and surface finish.

Flexible pumping aids provide efficiency by allowing the concrete to move further distances or through more complicated placement requirements without losing efficiency during the cold weather.

Cautions When Forming and Reinforcing the Concrete Formwork

Preparation of the Formwork

- The formwork should be cleared of ice, frost, and snow before pouring.

- Where possible, use insulated or nonmetallic formwork.

- Do not place concrete against frozen surfaces.

Metal formwork loses heat very quickly by transferring it away from the concrete. Insulated formwork would retain the heat generated during the curing process, which means that the hot concrete will continue to stay warm longer.

Reinforcement Protection

Steel reinforcement must be free from any freezing at the time of placing the concrete. If the steel is frozen, it will create an improper bond between the steel reinforcement and the concrete, and create uneven thermal distribution of heat from the concrete to the steel.

Concrete Placement Best Practices

Placing Concrete Quickly and Continuously

When concrete is placed, it should be done as fast and continuously as possible to reduce its exposure to cold air. Delays in placement increase the risk of the temperature dropping and of uneven set times.

Concrete Should Be Properly Compacted

The process of compacting the concrete will eliminate the trapped air in the concrete. Proper compaction will also decrease permeability and improve the ultimate strength of the concrete. Due to the increased stiffness of cold concrete, proper vibration leads to more effective vibration.

Curing of Concrete Must Be Done at a Controlled Temperature

Curing concrete is the most important part of the process for curing concrete during cold weather.

Temperature Maintenance

The concrete should be kept above 5 degrees Celsius (42 degrees Fahrenheit) for the first several days of curing. Methods to achieve this include:

• Using insulation blankets or sheets.

• Using thermal covers or curing mats.

• Using heated enclosures or temporary covering shelters.

Avoid Sudden Cooling

After initial strength gain, concrete should be allowed to cool gradually. Sudden temperature drops can cause thermal cracking.

Common Mistakes to Avoid

- Pouring concrete on frozen subgrades.

- Over-watering the mix to improve workability.

- Removing formwork too early.

- Ignoring night-time temperature drops.

- Performing finishing operations while the bleed water is still present.

Avoiding these mistakes significantly improves concrete performance in cold conditions.

Global Best Practices for Cold Weather Concreting

Whether you live in a tropical or arctic climate, the same research-proven principles used to successfully pour concrete in cold conditions apply everywhere. The basic principles for success are:

- Maintain Proper Temperature of Concrete7

- Protect Concrete from Frost Until Adequate Strength Has Developed

- Use Proper Admixtures & Pumping Aids to Allow for Ease of Use During Placing

- Provide For Proper Curing & Insulating Of Concrete

Because these four principles are global and not local, they can be utilized in construction projects regardless of the surrounding environment.

Why Choose Sakshi Chem Sciences for Cold Weather Solutions?

The benefits of working with Sakshi Chem Sciences for Cold Weather Concrete Solutions are numerous. For more than 20 years, Sakshi Chem Sciences has provided construction projects with innovative concrete admixture solutions for extreme environments.

Sakshi Chem Sciences offers the following benefits to your project:

– Our concrete mixing solutions are formulated through science; thus, we are confident our formulas will provide the added early strength desired by contractors working in cold weather.

– We offer Pumps and Aids designed for optimum performance to allow for effortless placement of concrete.

– You will benefit from our thorough quality control practices and established compliance with international regulatory guidelines.

– The only company in the world that provides both technical support and on-site assistance from a team of highly experienced construction specialists.

The benefits described above enable contractors to be as productive and quality-conscious as possible when pouring concrete in cold-weather environments.

Conclusion

When pouring concrete in cold weather, making the correct decisions at each step (controlling the temperature of the concrete, using appropriate admixtures, and the correct Pumping Aid) will go a long way toward protecting your concrete from end-of-service-life (ESL) frost damage.

As long as a contractor follows the principles outlined above, they can produce a durable, long-lasting, and safe structure that will stand the test of time without sacrificing quality during the process.

With the right approach and trusted solutions from Sakshi Chem Sciences, construction projects can move forward confidently, regardless of temperature challenges.

Sandip Agrawal, Polymer Engineer and MD of Sakshi Chem Sciences Pvt. Ltd., leads innovation in construction chemicals, shuttering oils, and industrial lubricants. With expertise in polymer science and eco-friendly solutions, he drives R&D and sustainable advancements, ensuring high-performance products for India and global markets.