Concrete forms the foundation of modern construction. From high-rise structures and bridges to residential buildings and sidewalks, concrete is both a material and a method that shapes our world today.

However, not all concrete is the same, and the decision of which concrete preparation type is right for your project is one of the biggest decisions to make on any project.

Table of Contents

The Ready-Mix Concrete vs. Mix-On-Site Concrete debate has long existed within the industry, with pros and cons of each, and deciding which to choose will directly impact your quality, cost, time, and sustainability.

In this blog, we will describe the difference between ready-mix concrete and mix-on-site concrete, including features of each, the pros and cons, and then you can determine which is best for your project.

Understanding the difference between Ready-Mix and Mix-On-Site Concrete

1. What is Ready-Mix Concrete?

Ready-Mix Concrete (RMC) is processed in factory factory-controlled environment, typically at a batching plant, where differing amounts of cement, aggregate, water, and concrete admixtures are added using equipment that ensures accuracy.

After batching, the concrete is returned to the job site in a transit mixer, which is equipped with a rotating drum to keep the concrete blended and plastic until it can be placed.

Some Fundamentals of Ready-Mix Concrete:

Factory Batching under factory-controlled quality specs.

Consistent mix and strength.

Delivered Ready to Use, no mixing at the location required.

Ready-Mix Concrete is ideal for large-scale projects that require high-quality concrete and faster execution.

2. What is Mix-On-Site Concrete?

”Mix-On-Site Concrete”, also known as site-batched concrete, is manually or machine-batched directly at the construction site. The components (cement, sand, aggregate, water) are measured and mixed at the location.

Although this allows flexibility for small adjustments, it can also introduce variability in mix quality, uniformity of strength, and consistency based on the abilities of the labor force and quality of materials used.

Noteworthy characteristics of Mix-On-Site Concrete:

Prepared directly at the project site – – Flexible proportionings for urgent needs – – Dependent on labor force for quality characteristic

Mix-On-Site is more common for small/medium projects, as well as in rural sites where access to a batching plant facility could be limited.

Benefits of Ready-Mix Concrete

1. Reliable Quality

Ready-mix concrete is prepared in automated plants with stringent controls on quality. Each batch is calibrated design work, pre-determined to ensure a constant proportion and strength of performance.

This is especially valuable for projects where the structural loads are high, such as bridge work, commercial towers or industrial floors, which often require some level of confidence in the finished concrete.

2. Time Saving

When the ready-mix is provided for pouring, the time and labor spent mixing, testing, dry-shaking, and modifying ingredients is saved at the job site; this saves time and is particularly making it easier on a rushed schedule for project completion.

3. Less Waste

Ready-mix concrete has very little wasted material due to the precise batching of desired ingredients. The same control over ancillary materials and ingredients unto to including moisture, also helps control hydration rates while using the minimal amount of cements and other materials that can be devised safely.

4. Workability

Using developed concrete additives along with slurry pouch technologies used with ready-mix makes keeping mix workability streamlined, along with fluidity on the sidewalk over distance, with variations of transit time.

This means that the concrete is easier to pump, spread, along with finishing with minimal labor time.

5. Sustainability

Using ready-mix reduces dust, pollution, and waste of materials at the site level, more responsible use of ingredients, along with site work for urban jobs.

Disadvantages of Ready-Mix Concrete

In summary of advantages, while RMC has a considerable amount of logistics, it could have a few downsides to consider.

comparatively higher cost per cubic meter (value spent in transportation or accessibility of batching plants).

Limited flexibility once the mix is in place (what is in place must be field work in a select amount of time).

The access to remote areas or drug stores that are not close to batching plants.

Ultimately, all of these downside issues, around RMC’s performance metrics can be accounted for with planning in relation to accessibility and availability.

Advantages of Mix-On-Site Concrete

1. Cost-Effective for Small Projects

Mix-on-site concrete negates the delivery cost associated with ready-mix, making it ideal for local and low-volume projects.

2. Flexibility in Mix Design

Contractors may fine-tune the cement, sand, and aggregates proportions as needed on-site, given a specific requirement(s) or environmental circumstance.

3. Nowhere But on-Site Availability

Concrete can be mixed and used instantly without waiting for any delivery.

Disadvantages of Mix-on-Site Concrete

However, there remain disadvantages faced by the quality and logistics of mix-on-site concrete preparation:

Inconsistent Quality: Because the strength is the last variable in the concrete construction process, unpredictably varying material measurement, water volume, or duration of mixing each introduces variability of strength.

Labor Intensive: Mixing and placing concrete by hand can be exhausting and will require the use of extra labor.

Wastage: Additional waste produced is a function of cleaning, spillage, and variation from too much material being mixed.

Space Needed: Raw materials will require sufficient space on site, and sometimes excessive space for urban areas.

Time Delayed: Longer duration is associated with mixing, testing, and curing concrete.

In the evaporation and high precision projects, any of the above factors can mean the differences in both structural integrity and appearance.

Comparing Ready-Mix and Mix-On-Site Concrete

| Feature | Ready-Mix Concrete | Mix-On-Site Concrete |

| Preparation | Prepared in batching plants using automated systems | Mixed manually or using small mixers on-site |

| Quality Control | Consistent due to computer-controlled batching | Depends on operator skill and material quality |

| Time Efficiency | Faster application, minimal preparation | Slower; mixing and curing time needed |

| Cost | Slightly higher due to logistics | Lower for small quantities |

| Waste Generation | Very low | High wastage from leftover materials |

| Storage Space | No raw materials stored on-site | Requires storage space for sand, cement, aggregates |

| Workability | Enhanced by admixtures and slurry pouch technology | Variable; manual adjustment needed |

| Suitability | Ideal for large projects | Best for small-scale or rural works |

The Role of Concrete Admixtures and Slurry Pouch Technology

Modern concrete relies primarily on chemical admixtures and performance enhancers. These materials modify the properties of concrete to increase workability and durability, add sustainability, etc.

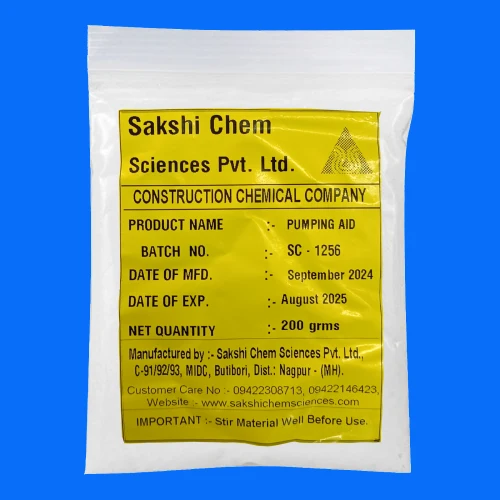

At Sakshi Chem Sciences, we provide several high-performance admixtures for both ready-mix concrete and site-mix concrete. The most popular admixtures we offer are:

- Water-reducing admixtures

- Retarders and accelerators

- Superplasticizers

- Air-entraining agents

- Shrinkage reducers

Additionally, slurry pouch technology, additive packets that are pre-measured, is revolutionizing how admixtures are deployed on the job site. Each pouch is filled with concentrated chemical additives that can be easily mixed with water or poured directly into the concrete at the time of mixing.

The product pouches help to ensure accurate dosing while avoiding the bulk weight of handling the chemical.

Slurry pouch technology increases convenience, safety, and quality control on construction projects.

Which Option Should You Choose?

Choose Ready-Mix Concrete when

- Your concrete application requires high-quality, uniform concrete.

- You are running a due deadline with an enormous amount of construction or large project framework.

- You want less wastage and site management headaches.

- Your project location is close enough to the city’s batching plant.

Choose Mix-On-Site Concrete when

You have a small concrete project or a project framework that is geographically or logistically distant from a batching plant

You want to be flexible in changing the mix and adjusting the mix multiple times on-site

The pricing and cost model of ready-mix concrete outweigh the quality you are aiming for

In reality, it is common for builders to implement both methods; builder uses ready-mix for structural components while site-mix can be used for smaller or final work on site.

Conclusion

The best method is generally dictated by scale, location, and performance demands of your project regarding the choice between Ready-Mix Concrete vs. Mix-On-Site Concrete.

Ready-mix provides precision, speed, and reliability, and site-select can provide flexible and cost control for site-mixing smaller projects; and both systems can perform durable and high-performing concrete designs with the proper additives. This is especially true with new additives such as slurry pouch admixtures.

According to Sakshi Chem Sciences, we strive to make building construction smarter, cleaner, and cost-efficient. All of our products, including concrete admixtures, tile adhesives, and waterproofing, are developed to fulfill market demand and project needs in the ever-changing world of construction.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.