Introduction

When constructing reinforced concrete structures, half the equation is strength and the other half is durability. This is where the small, yet remarkable concrete cover block comes into play to safeguard the reinforced steel quietly within the concrete.

These covers are crucial because they protect the reinforcement bars (rebars) from moisture, chemicals, and thermal changes. Without them, corrosion will inevitably eat away at the steel, jeopardizing the integrity of the whole structure.

Table of Contents

At Sakshi Chem Sciences Pvt. Ltd., we understand that small details make for major differences in the long-term performance of a structure. With 20 years of consumer expertise in construction chemicals, concrete admixtures, corrosion inhibitors, and protection systems, we understand that picking out the right concrete cover block is much more than a design decision; it is an insurance policy for your project tomorrow.

In this blog, we will look at the following:

What concrete cover blocks are and what their importance is?

What are the different types of concrete cover blocks are?

What factors should you consider when picking out the right concrete cover block?

How additives such as corrosion inhibitors complement concrete cover blocks to help ensure maximum durability?

What is a Concrete Cover Block?

A concrete cover block (also known as a spacer block) is a small block made of concrete, plastic, or fiber-reinforced materials. Its primary function is to provide adequate spacing between rebars and the outside surface of the concrete so that the rebar material has sufficient concrete cover. Adequate concrete cover protects the reinforcement from:

- Moisture and water ingress.

- Chlorides in coastal environments or industrial situations.

- Carbonation from exposure to air.

- Heat is when a structure catches on fire.

In summary, cover blocks provide the minimum thickness of concrete cover that a design code requires, preventing premature corrosion of rebar and extending the life of the structure.

The Importance of Concrete Cover Blocks

Concrete cover blocks do not seem very important, but cover blocks have critical importance in every reinforced concrete structure. The importance of concrete cover blocks can be summarized as:

Corrosion Protection

Rebar is very likely to rust under moisture and chlorides. Cover blocks provide a cushion between the steel and the environment, and they are often used with corrosion inhibitors for double protection.

Fire Resistance

When a fire occurs, adequate concrete cover retards the heat from getting to the rebar for a longer period, keeping the structure intact longer.

Load Transfer

Cover blocks provide uniform spacing and better distribute load stress through a structure.

Durability

An appropriate cover block ensures durability in construction with little damage.

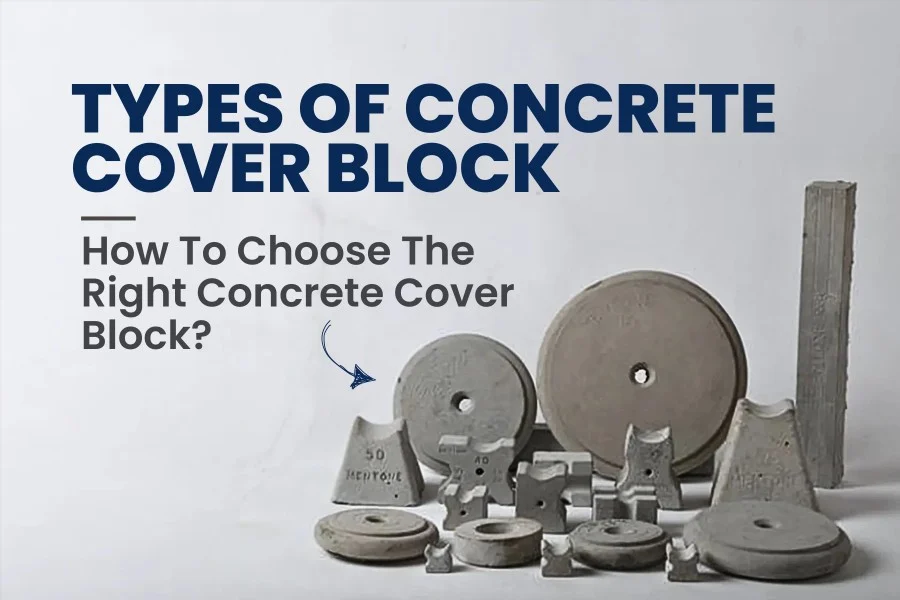

Types of Concrete Cover Blocks

Concrete cover blocks are classified according to the material of the concrete blocks and the type of application. Here are the main types:

1. Concrete Cover Blocks

Composed of cement, sand, and aggregate, concrete cover blocks are the most common type.

They have similar thermal expansion to concrete, so the risk of cracking is reduced.

These cover blocks are best used in beams, slabs, and columns.

Concrete cover blocks can come in many sizes (15 mm, 25 mm, 40 mm, etc.)

Pros: Durable, strong, style compatible with reinforced concrete.

Cons: Brittle and may crack during handling.

2. Plastic Cover Blocks

Plastic cover blocks are made of high-strength plastic (usually recycled).

They are lightweight and easy to handle.

They are non-porous and do not absorb water.

Pros: Cost-effective, does not corrode, and is predictable in size.

Cons: Different thermal properties than concrete, which may result in micro-gaps.

3. Fiber-Reinforced Cover Blocks

Fiber-reinforced cover blocks are made of cement, sand, and either polypropylene (PP) or glass fibers.

These cover blocks are stronger than normal whole concrete cover blocks.

They flex better, resulting in improved crack resistance, dimensional stability, and durability.

Pros: High load-bearing capacity, crack resistance, service life.

Cons: Slightly higher cost.

4. Metallic Cover Blocks

Metal cover blocks can be made of mild steel or aluminum.

They are not commonly used except in temporary structures.

Pros: They are strong and convenient for short-term applications.

Cons: They are easily corroded and typically unsuitable for permanent structures.

5. Specific Cover Blocks

Used in unique applications such as marine structures, bridges, and industrial plants.

In some cases, they can have corrosion inhibitors in the mix to give added longevity.

How to Choose the Right Concrete Cover Block?

To choose the right concrete cover blocks, you need to think closely about structural design and the environment, and the overall durability required. Here are the considerations to be mindful of:

1. Comply with Building Codes

You should select the cover blocks that comply with the IS code, ACI, and Eurocode. These codes state minimum cover thicknesses based on general structural elements and activities of the structure.

2. Environmental Conditions

With marine conditions, use concrete cover blocks that are higher in density and use corrosion inhibitors.

When used in industrial conditions, select fiber-reinforced blocks that are resistant to chemical attack.

In normal residential construction, a standard concrete block will suffice.

3. Kind of Structure

High-rise buildings: The use of long, durable life fiber-reinforced blocks.

Bridges & tunnels: A thicker cover with corrosion resistance.

Residential slabs will use either ordinary concrete cover blocks or preservatives to justify their limited life expectancy.

4. Durability & Load Requirements

Heavier load-bearing elements like beams and columns require high-strength concrete cover blocks, whereas non-load-bearing elements can use lightweight alternatives.

5. Integration with Concrete Admixtures

When used with concrete admixtures (like superplasticizers, retarders, or waterproofing agents), cover blocks enhance overall performance by ensuring the concrete retains its designed cover properties.

The Role of Corrosion Inhibitors with Concrete Cover Blocks

Steel can corrode even with adequate concrete protection in severe conditions. That’s why corrosion inhibitors can be a helpful partner.

Corrosion inhibitors are chemical admixtures that are added to concrete to inhibit or prevent the electrochemical reactions that cause steel to corrode. When used with the right cover block, they:

Enhance the longevity of reinforcement.

Minimize maintenance costs.

Increase the durability of structures in aggressive conditions, e.g. coastal zones.

At Sakshi Chem Sciences, we are a manufacturer of the highest quality concrete admixtures and corrosion inhibitors that are designed to be combined with concrete cover blocks to help create long-lasting structures.

Uses of Concrete Cover Blocks

Concrete cover blocks are used in:

- Residential structures – slabs, beams, and towers.

- Bridges and flyovers require a thicker protective cover.

- Tunnels and below-ground structures – where moisture is ever-present.

- Marine and coastal project – where the chloride attack is problematic.

- Industrial facilities – where exposure to chemicals is present.

Best Practices and Maintenance

- Use high-quality cover blocks with uniform dimensions.

- Cure properly to avoid cracks caused by curing cover blocks.

- Regularly check exposed areas for spalling or damage to the cover.

- Use with a corrosion inhibitor in a high-risk environment.

- Never replace a cover block with random stones or pieces of wood – this is a durability risk.

Sakshi Chem Sciences: Your Trusted Partner in Durability

At Sakshi Chem Sciences Pvt. Ltd, we don’t just sell products. We provide solutions that work in construction for the long run. We have the largest product range of construction chemicals in India, which includes:

- Concrete admixtures for improved workability and strength.

- Waterproofing agents for moisture resistance.

- Corrosion inhibitors to protect reinforcement steel.

- Repair and rehabilitation products that increase longevity.

Our products are developed according to rigorous international criteria, so you can be confident in them for your domestic and international projects.

With 20 years of experience, strong R&D, and a modern manufacturing facility, we now regularly export to the Middle East, Africa, Europe, and Southeast Asia, and are proud to be India’s largest exporter of construction chemicals.

Conclusion

The concrete cover block is not just a spacer; it is a structural protector, a durability enhancement, and a silent guardian of reinforced concrete. Your choice of cover block depends on a multitude of factors, such as the environment the structure was built in, the type of structure, and the load on the structure.

When used with corrosion inhibitors and concrete admixtures, cover blocks promote the life-long strength of your structure against time, weather, and chemical attack.

At Sakshi Chem Sciences, we want to help you make the right decision for sustainable, long-lasting construction.

Frequently Asked Questions (FAQs)

1. Why are concrete cover blocks important?

Cover blocks safeguard reinforcing steel from damage caused by corrosion, fire, and other environmental factors.

2. What are the primary types of concrete cover blocks?

Concrete, plastics, fiber-reinforced, metallic, and specialty cover blocks.

3. How do I select the appropriate cover block?

Take the environment, structural criteria, load capacity, and building code compliance into account when selecting a cover block.

4. Can corrosion inhibitors take the place of cover blocks?

No, they are designed to be used in conjunction with providing additional corrosion protection for reinforcing steel.

5. What is the consequence of using no cover blocks?

Poor cover spacing will only increase the likelihood of early corrosion and cracking, and the overall service life of the structure will be reduced.

6. Are plastic cover blocks durable?

Yes, they are lightweight and oxide-free, although they are not as compatible with concrete as cement-based cover blocks.

7. Do building codes require a minimum thickness of cover?

Yes, IS codes and global codes set a minimum thickness based on exposure condition and structural type.

8. How do I ensure that my cover blocks will last over time?

Use quality cover blocks, re-cure concrete when complete, inspect often and when possible, combine admixture and corrosion inhibitors.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.