Understanding the use of admixtures in concrete – and why it matters more than you think

When it comes to construction and civil engineering, concrete is often regarded as king. It is strong, durable, and flexible. However, one lesser-known fact is that concrete’s success does not merely depend on the use of cement, sand, and water.

It is also extensively dependent on a group of secret ingredients called admixtures, and two of the most typical admixtures are plasticizers and superplasticizers.

Table of Contents

Now, unless you are involved with construction on a daily basis, the terms plasticizer and superplasticizer may not mean much to you. However, knowing the difference can help you better understand how our buildings are becoming stronger, longer-lasting, and more efficient as we learn more about how to use these ingredients in concrete.

Our intention is to provide you with an enjoyable, human-friendly article whether you are a student just curious, someone who is interested in construction, or just getting started thinking about building materials for your new project.

What Are Plasticizers and Superplasticizers?

Let’s look at the basics. Plasticizers and superplasticizers are chemical admixtures that are added to concrete to improve the workability – i.e. how easy it is to mix and pour and place concrete. However, they do this differently and to different extents.

Plasticizer (aka Water Reducer)

Primary purpose: improve the workability of concrete by reducing the water content needed for a given consistency.

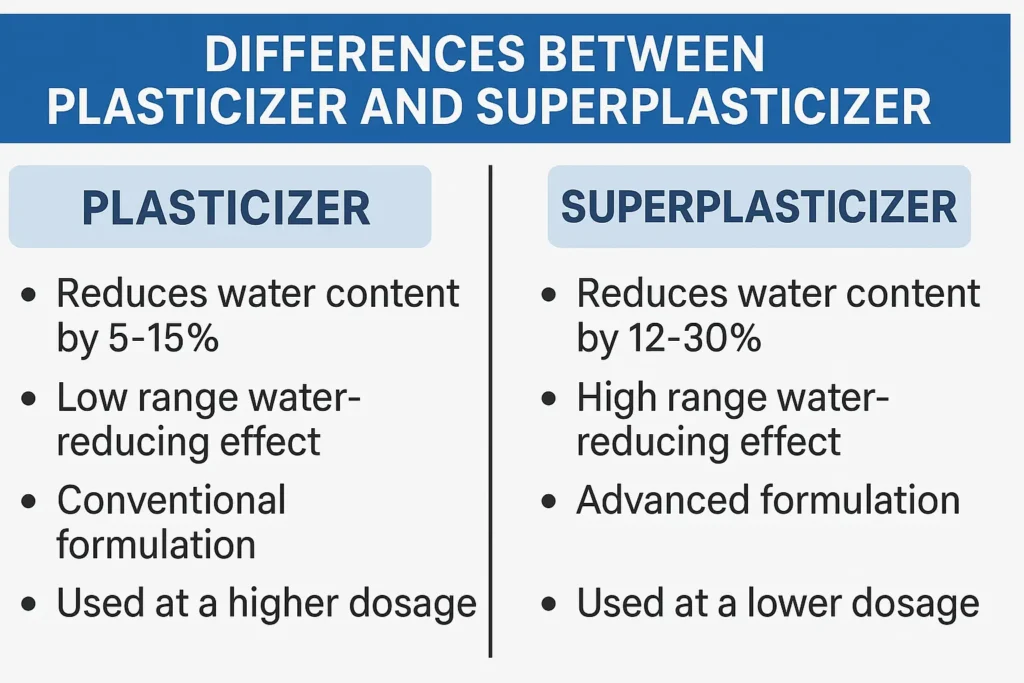

Water Reduction Capability: approximately 5% to 15%.

Concrete effect: makes it easier to handle and pour without dramatically affecting its performance characteristics.

Superplasticizer (aka High-Range Water Reducer)

Primary purpose: considerably improve the flow and workability of concrete, particularly for high performance applications.

Water Reduction Capability: approximately 12% to 30%.

Concrete effect: allows for much higher strength, better compaction, and decreased porosity even at low water content.

So both are used to try to make concrete easier to work with. The superplasticizer just does it in a bigger way.

Why Is Reducing Water Important in Concrete?

That is a great question. Concrete needs water to hydrate and to harden, but too much water can damage your concrete. The more water you add, the more pores in the hardened concrete, and the less durable it will be.

Plasticizers and superplasticizers help us by lessening the amount of water necessary for workability without sacrificing your mixtures integrity. This gives us:

- Stronger Concrete.

- More Durable Structures.

- A better finish and aesthetics.

- Less chance of cracks or shrinkage.

Key Differences Between Plasticizer and Superplasticizer

Let’s break this down into a more practical, human-understandable format:

| Feature | Plasticizer | Superplasticizer |

| Water Reduction | 5–15% | 12–30% |

| Workability Enhancement | Moderate | High |

| Application Areas | General construction, low-rise buildings | High-strength concrete, bridges, skyscrapers |

| Effect Duration | Shorter | Longer (but varies by type) |

| Cost | Less expensive | More expensive |

| Dosage | Typically 0.1%–0.5% of cement weight | 0.5%–2.0% of cement weight |

| Chemical Base | Lignosulfonates, hydroxycarboxylic acids | Sulfonated melamine/formaldehyde, polycarboxylate ethers (PCE) |

Related Post: How to Choose the Right Superplasticizer for Your Concrete?

A Closer Look at Their Chemical Behavior

If you are interested in the science part of it, here’s a kind of short explanation:

Plasticizers, usually made from lignosulfonates, work by dispersing cement particles to stop them sticking together. This allows for greater plasticity in the concrete mix (more flow) without needing to use more water.

Superplasticizers, and especially the modern plasticizers based on polycarboxylate ethers (PCE), are even better and allow the cement particles to spread out, bond and react with water more freely than a regular plasticizer, which is why the flow is much greater even with more solid content in the mix.

You can think of it as pancake batter, in which plasticizers could make your batter more fluid, but superplasticizers could make a hard lump of batter pourable without adding more milk.

Use Cases: When to Use Which?

You might be asking yourself—if superplasticizers are so effective, why don’t we use them every project? It all comes down to your project needs:

When Should Plasticizers Be Used:

When it is an uncomplicated residential building or a non-structural application

When moderate improvement in workability is adequate

When cost is a consideration

For the precast elements that do not have demand ultra-high strength

When Should Superplasticizers Be Used:

When it is a major infrastructure project like a bridge, dam, tunnel, or high-rise

When you need a high-performance concrete with superior strength

In hot weather for extending/set delaying time

For self-compacting concrete (SCC) that has to fill every void of a form

When the durability and impermeability—a chief concern.

In other words, plasticizers are beneficial for standard requirements. Superplasticizers are used when you are transitioning to high strength, prolonged life, or architecture finesse.

How They Effect the Set Time?

Another interesting point of comparison is the effect on set time.

Plasticizers typically have little effect on the set time.

Superplasticizers may delay (give time) or may accelerate (slightly) sets, depending on the superplasticizer type.

For hot climates or extremely fast-paced construction sites, this is a benefit. Superplasticizers help offer more time for placing and finishing the concrete prior to it setting.

Challenges and Considerations

While these admixtures may sound amazing, one thing to remember is that they are not plug and play. Here is a brief list of what to be aware of:

With Plasticizers:

You can add too much and you’ll get segregation of the mix.

If the mixing process is not done correctly or if the product is not stored correctly, the effectiveness could be reduced.

With Superplasticizers:

There can be rapid slump loss (stiffening of the mix) in very short time frames.

Compatibility with other admixtures (air entrainers) will need to be evaluated.

The cost is greater, therefore the use of fun admixtures needs to be justified in meeting performance specifications.

What’s the bottom line? Connect with seasoned engineers and/or laboratory technicians to assess the preliminary mix before totally committing to the price tag of the admixtures.

The Evolution: Plasticizers to Superplasticizers

The construction industry has certainly progressed over the decades and have gone from basic admixtures to more advanced formulations.

In the seventies and eighties, we first saw the introduction of the older generation of superplasticizers (such as naphthalene- or melamine-based)

Now, we have polycarboxylate ether (PCE) superplasticizers that allow ultra-fluid concrete mixes at very low water-cement ratios.

If you are an innovator and want to build in the future, it is not just academic to understand the plasticizer vs. superplasticizer difference; it is fundamental.

Related Post: What Is The Role and Advantage of Polycarboxylate Superplasticizer?

Wrapping It All Up: Which One Should You Choose?

Nothing beats a simple answer with complexity: that depends upon your project goals.

Do you want an inexpensive way to improve workability? Use a plasticizer.

Do you need high-strength, durable, flowable concrete? Use a superplasticizer.

Understanding how these admixtures behave not only allows you to choose the right product, but better concrete with cost savings and improved sustainability through reduced water and cement use.

That is why great construction is all about good choices through science and experience.

Final Thought

Next time you are standing at a bridge or building or even at your neighborhood sidewalk, consider that it is not just rocks and cement keeping everything together. It is chemistry in action. And plasticizers and superplasticizers are mixing it up quietly, powerfully, and importantly.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.