Concrete is a crucial part of infrastructure in the modern world. Whether for bridges and roads, buildings, to factories, concrete can provide the strength and durability construction requires to endure time and external pressures.

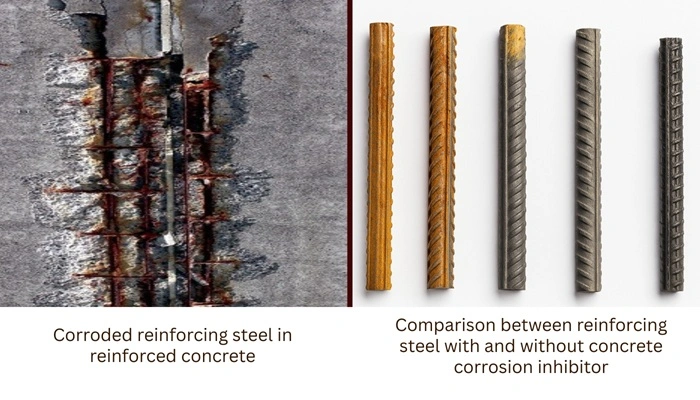

In turn, concrete’s vulnerability lies in the corrosion of reinforcing steel. Once corrosion begins, this issue reduces strength, contributes to life expectancy, weakens the structure, and triggers expensive repairs.

Table of Contents

At this juncture, corrosion inhibitors in concrete become important. When recommended, these additives, inhibitors, can extend the service life of the concrete structures, alleviate premature failures, and sustain longer functionality.

In this blog by Sakshi Chem Sciences Pvt. Ltd., we will explain what corrosion inhibitors are, their functions, types, and, most importantly, best practices to incorporate corrosion inhibitors into concrete that will improve performance.

Understanding Corrosion in Concrete Structures

Concrete structures are typically reinforced with steel reinforcement (rebar) to withstand tension loads. Concrete does provide an environment that is alkaline to protect and preserve steel. However, either naturally or externally, the reinforcement of steel’s passive layer is disrupted.

Common Causes of Corrosion

Chloride Ion Penetration

The chlorides causing the corrosion come from de-icing salts (road salts), the marine environment, or contaminated aggregates, which can all destroy the passive oxide film of steel.

Carbonation

When carbon dioxide reacts with calcium hydroxide, this reduces the pH.

This creates a less alkaline environment, making steel more vulnerable.

Moisture & Oxygen

The combination of oxygen and water accelerates rusting once the steel’s protective film is compromised.

When steel corrodes, the rust expands up to six times its original volume. This expansion creates internal pressure, causing cracks, delamination, and spalling of the concrete. Beyond aesthetics, this directly impacts the safety and longevity of the structure.

What Are Corrosion Inhibitors in Concrete?

Corrosion inhibitors are chemical admixtures or surface treatments that reduce the rate of corrosion in reinforced concrete. They work by:

- Maintaining alkalinity around the steel.

- Forming a protective barrier (passive film).

- Blocking or neutralizing aggressive ions like chlorides.

Inhibitors are important in preserving the structural integrity, durability, and service life of concrete elements because they slow or prevent corrosion.

Types of Corrosion Inhibitors

Corrosion inhibitors in concrete are not all the same. They differ in chemical composition, mechanisms of action, and suitability to various environments.

85307 84949The type to be selected will depend on the exposure conditions, the structural intent, and end-of-life durability objectives. We will now explore types of inhibitors in further detail:

1. Anodic Inhibitors

Anodic inhibitors are among the most common types used in reinforced concrete. Anodic inhibitors work by creating a stable, protective oxide film on the steel reinforcement. The protective layer makes it difficult for chloride ions or carbonation to penetrate and attack the steel surface.

Example: The most common anodic inhibitor is calcium nitrite.

Operating Mechanisms: Calcium nitrite increases the potential of the steel and helps promote passivation of the steel.

Benefits: Anodic inhibitors are very beneficial in locations where the primary risk of corrosion is chloride-induced corrosion, such as bridges in coastal regions, marine structures, and parking garages.

Points of Caution: Calcium nitrite must be dosed correctly. Under-dosing provides no full protection, and overdosing can modify the setting time of the concrete slightly.

2. Cathodic Inhibitors

Cathodic inhibitors have an alternative operating mechanism. Instead of forming a film, they slow down the oxygen reduction reaction at cathodic sites on the steel surface. This reduces the overall rate of corrosion, even if the process has already started.

- How it works: They regulate the diffusion of electrons throughout the steel’s corrosion process.

- Best Fit: Where oxygen is significantly involved in the acceleration of steel corrosion, such as in humid and well-ventilated locations.

- Benefits: Useful when it is not possible to completely control chloride ingress.

- Disadvantages: Alone, they may not be suitable for very aggressive environments, and when they are used, they are typically part of a larger strategy to protect steel.

3. Mixed Inhibitors

As the name implies, mixed inhibitors provide dual mechanisms of protection. They are effective in protecting the steel at both the anodic and cathodic sites, which enhances their flexibility and reliability in a wide range of conditions.

- How is this accomplished: They protect the steel by forming a thin protective film on the rebar (similar to anodic inhibitors) and reducing oxygen reduction reactions (similar to cathodic inhibitors).

- Benefits: These provide protective barriers against both types of sites, therefore, they are effective in more complex environments, such as in urban structures where pollution, coastal air, and de-icing salts are a concern.

- Uses: With their all-around protective features, they are common in infrastructure types of projects (highway pavements, airports, and large commercial buildings) where durability is extremely important.

4. Organic inhibitors

Organic corrosion inhibitors consist of nitrogen, oxygen, or sulfur based compounds. They bond to the steel surface, creating thin, hydrophobic layers to repel water and chloride ions from contact with the steel.

- Examples: Amines, carboxylates, and fatty acid derivatives.

- Advantages: Highly effective in preventing moisture-related corrosion. They also tend to improve concrete workability in some cases.

- Applications: Ideal for areas with high humidity or frequent rainfall, such as tropical climates.

- Considerations: Dosage and compatibility with other admixtures should be carefully checked, as organic compounds can sometimes alter setting times or early strength gain.

5. Green / Eco-Friendly Inhibitors

With the construction industry moving towards sustainability, eco-friendly corrosion inhibitors are gaining global attention. These are derived from natural, biodegradable sources and aim to minimize environmental impact while still offering protection.

- Examples: Plant extracts such as ginger root, olive leaves, guar gum, chitosan, and Fatsia japonica.

- How they work: Active compounds in these extracts adsorb onto the steel surface and form a protective film, slowing down corrosion reactions.

- Advantages: Environmentally safe, renewable, and often cost-effective. They also align with green building certifications like LEED.

- Challenges: Research is still ongoing to improve their consistency and long-term efficiency compared to synthetic inhibitors.

Benefits of Using Corrosion Inhibitors in Concrete

The advantages of corrosion inhibitors go well beyond simply preventing rust:

Increased Service Life: Shields rebar, ensuring the structure lasts longer.

Lower Maintenance Expenses: Decreases the frequency and expense of repairs.

Load Capacity of Structural Integrity: Provides load capacity without damage to equipment or personnel.

Environmentally-Friendly Options: Green inhibitors have less impact on the environment.

Cost Savings: May remove the need for complex protective methods in many situations.

In a situation of projects with marine exposures, on coastal areas, bridges, highways, and industrial plants, corrosion inhibitors are not a choice; they are a necessity.

Best Practices When Using Corrosion Inhibitors in Concrete

To maximize efficiency and long-term performance, corrosion inhibitors must be appropriately and accurately applied. A proper plan will not only provide better protection but also save time and cost later.

The following are the best practices throughout the industry that every construction personnel should follow:

1. Select the right inhibitor applicable to the exposure conditions.

Not all structures present the same risks; therefore, selecting the appropriate inhibitor for the environment is important.

For marine projects where chloride attack is ongoing → anodic-type inhibitors, such as calcium nitrite, are better performing.

For high humidity/industrial use and under extreme conditions → organic inhibitors with hydrophobic properties are applicable and offer additional barrier resistance.

For mixed or unpredictable exposures → mixed-type inhibitors offer balanced, all-round protection.

Selecting the wrong inhibitor can result in poor performance, so matching the chemical to site conditions is essential.

2. Ensure Proper Dosage and Mixing

Proper dosage is important for their proper function.

Always adhere to the dosage recommendation provided by the manufacturer. The recommended dosage is a tested value backed by research.

An overdose may change the set time or reduce concrete’s compressive strength.

An underdose may limit the inhibitor’s functionality and leave the steel unprotected.

Evenly introducing the inhibitor into the concrete matrix is equally important, as culture points of corrosion weaken the concrete.

3. Use in conjunction with other protective methods

Corrosion inhibitors are effective, but combining the inhibitor with other protective measures ensures multi-layered protection.

For example, waterproofing products, sealers, and surface coatings should are used in conjunction with inhibitors will provide additional layers of safety.

Together, these materials will help protect the rebar from moisture and chemical intrusion before entering the concrete, extending the concrete structure’s lifespan.

4. Take advantage of early-stage integration

The sooner the inhibitor is integrated, the better the effectiveness of the inhibitor.

Incorporating liquid inhibitors directly into the fresh concrete can help achieve a more uniform distribution and immediately begin protection.

For existing or older structures, surface-applied penetrations and coatings can also provide benefits; however, they won’t give you the level of benefit of an early-stage integration.

Usually, the earlier an inhibitor is integrated, the fewer associated or expensive retrofits for corrosion development will be needed later.

5. Material qualities

Even the best inhibitor doesn’t overcome poor-quality raw materials.

Use cement of high quality with well-graded aggregate; always use reliable admixtures too.

Low-quality materials often have impurities that can intensify corrosion and reduce the effectiveness of inhibitors.

Keep in mind: Inhibitors increase durability, but they require a solid foundation upon which to work.

6. Conduct Regular Monitoring

Corrosion monitoring is not an immediate failure process, but a long-term, progressive threat.

Regular testing through half-cell potential measurements or corrosion rate measurements, are technique to determine inhibitor performance.

Monitoring can help identify corrosion early: this allows you to take action before major damage occurs.

A proactive approach can save significant repair costs over the structure’s life.

7. Pair with Good Construction Practices

Corrosion inhibitors should never seek to replace good construction practices; rather, they are a complement.

Proper curing, sufficient cover depth for reinforcement, and a low water-cement ratio should always be the standard practice.

These types of practices increase structural durability and ensure extended service life, sometimes decades, when paired with inhibitors.

Green Corrosion Inhibitors: A Path Towards Sustainable Construction

As our world moves toward sustainability, interest is growing in green corrosion inhibitors. Some “green” inhibitors come from natural sources such as ginger root extracts, olive leaves, and plant-based polymers. Laboratory studies show promising results.

Advantages of green inhibitors are:

- They are biodegradable and non-toxic.

- They work in chloride-rich environments.

- Align with global sustainability goals for green buildings.

At Sakshi Chem Sciences, we are committed to researching and promoting eco-friendly solutions that balance performance with sustainability.

Case Studies and Real-World Applications

Building Bridges in Coastal Areas

Utilizing calcium nitrite-based inhibitors extended a bridge’s life by 15 years compared to unprotected concrete.

Industrial Plant Floors

Using organic blended inhibitors cuts maintenance costs by 30%.

Repair of Old Structures

Surface applied inhibitors stopped the corrosion in structures over 25 years old without having to pay for expensive demolition.

These instances are just a few that illustrate how the proper use of inhibitors can provide cost savings and increase the useful lifespan of structures.

The Future of Corrosion Inhibitors in Concrete

The corrosion inhibitor market for concrete has strong growth potential due to –

Worldwide investment in infrastructure.

Smart materials have been developed to include AI and IoT for real-time monitoring.

Eco-friendly demands have created the need for sustainable inhibitors.

Corrosion inhibitors will be an important force in the future of long-lasting structures, especially with the global market expected to exceed USD 17 billion by 2031.

Conclusion

Concrete is strong, but without protection, it is still going to fail due to corrosion. Developers, engineers, contractors, and builders can use corrosion inhibitors in concrete to add protection, decrease costs, and increase sustainability.

Sakshi Chem Sciences Pvt. Ltd. offers heirloom-quality corrosion inhibitors, as well as a full range of other construction chemical products. For the past 20 years, we have had the benefit of quality R&D laboratories and a global supply chain to support our customers, which involves longevity and efficiency.

Choosing the right corrosion inhibitor is not just about protecting concrete—it’s about protecting investments, ensuring safety, and building a sustainable future.

FAQs

Q1. What are corrosion inhibitors in concrete?

Corrosion inhibitors are chemicals that act as admixtures to protect reinforcing steel in concrete against corrosion by providing a protective layer while maintaining a high alkaline state in the concrete.

Q2. Can I add corrosion inhibitors to fresh concrete?

Yes, many inhibitors are specifically designed to be mixed into fresh concrete during batching for an even layer of protection.

Q3. Are there corrosion inhibitors that can be used on existing structures?

Yes, surface-applied or penetrating corrosion inhibitors can be applied to existing concrete that is showing incipient signs of corrosion.

Q4. Are green corrosion inhibitors just as effective?

Yes, plant-based corrosion inhibitors such as olive leaf extract and chitosan have proven to be very effective while being sustainable and environmentally friendly.

Q5. Where are corrosion inhibitors most beneficial?

Corrosion inhibitors are most useful and necessary for structures located in coastal regions, bridges, highways, industrial plants, and land structures that are subjected to de-icing salts.

Q6. Do corrosion inhibitors affect the strength of concrete?

When used at the correct dosage, corrosion inhibitors will maintain structural properties in the concrete while not imparting any detrimental strength reductions.

Q7. How long do corrosion inhibitors last in the concrete?

Remember that this is dependent on the type of corrosion inhibitor, dosage, and level of exposure, but generally, corrosion inhibitors will last for decades when applied properly.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.