Concrete has been a trusted building material for centuries. Its strength, versatility, and relatively lower cost are making it an important part of modern infrastructure: bridges, tunnels, high-rise, and residential construction.

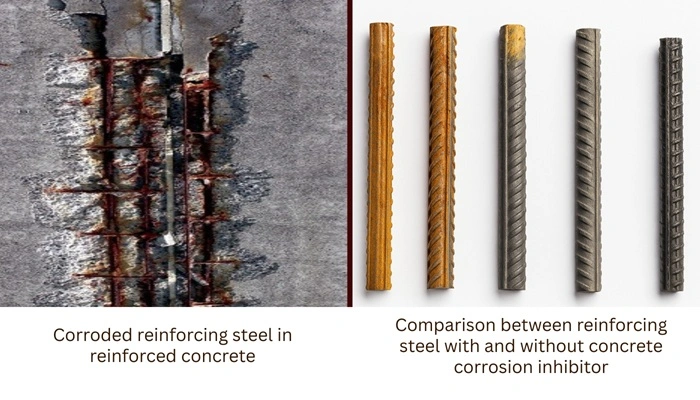

But despite the reputation as a reliable, trustworthy, and known material, concrete does have one major weakness – the corrosion of embedded steel rebar.

Table of Contents

The corrosion of steel reinforcement not only weakens the integrity of the structure but can also pose possible safety risks and risks of expensive repairs. This is the importance of Corrosion Inhibitors for the durability of concrete.

Corrosion Inhibitors for the durability of concrete are engineered solutions developed to protect reinforcement steel, add service life to concrete structures, and improve durability for long-term service.

At Sakshi Chem Sciences Pvt Ltd, we understand that it is essential to be able to build durable, safe, and sustainable buildings. After 20 years of experience, we developed corrosion inhibitors designed and manufactured to the best practice attributes of mainstream recognized global standards that provide long-term performance benefits for buildings and infrastructure projects.

Let’s explore the details on why corrosion inhibitors are so important and how they help to improve the durability of concrete.

1. Reinforcement protection

Steel reinforcement is critical to the structural performance of concrete in that it provides tensile strength for resisting concrete’s compression load-bearing capacity.

However, when exposed to moisture, oxygen, and chloride ions, steel is susceptible to corrosion. Eventually, this causes cracking, spalling, and possibly structural failure.

Corrosion inhibitors serve as a protective barrier around the reinforcement steel and prohibit corrosive elements from attacking the steel. By preserving the integrity of the steel, corrosion inhibitors help ensure the concrete structure will perform to its designed load-bearing capacity and prolong the project’s service life of the project.

2. The Mitigation of Chloride-Induced Corrosion

Chloride penetration is one of the greatest threats to reinforced concrete, especially in marine environments, coastal areas, or where de-icing salts create exposure. Chloride ions will enter the concrete and damage the passive oxide layer surrounding the steel, initiating corrosion.

Corrosion inhibitors were designed to eliminate the detrimental effects of chlorides, either working to block chloride penetration or by forming a protective film on the steel surface that stops corrosion before it begins.

This makes them extremely valuable to projects in coastal cities, industrial areas, or humid climates where chloride exposure is unavoidable.

3. Improved Durability in Harsh Environments

Concrete structures undergo harsh environments, specifically rapid cycles of temperature variations, humidity, freeze-thaw action, and chemical interaction with sulfate or acidic exposure. These environments increase corrosion and reduce durability.

Corrosion inhibitors increase the durability of concrete by mitigating the effects of these external factors. This allows concrete in places such as industrial facilities, marine environments, and areas of severe weathering to perform structurally and reliably even when the concrete has been subject to corrosive agents.

4. Extended Service Life

One of the main benefits of corrosion inhibitors is that they can enhance the lifespan of concrete. By preventing corrosion from occurring, the need for repair, rehabilitation, or replacement is less frequent, saving time and money in the process.

At Sakshi Chem Sciences, we recommend corrosion inhibitors for infrastructure projects with large multi-story buildings, highways, and tunnels where long-lasting infrastructure is important. The enhanced service life also lends itself to sustainable construction by reducing material waste and process.

5. Increased Safety

Safety is always important in construction. Corroded reinforcement contributes to the reduction of the properties of the concrete; this may cause cracks or full failure. This is a significant risk to occupants or users of that building.

Corrosion inhibitors can increase safety by preventing degradation of the steel and allowing concrete to perform as it should under certain conditions.

They protect not only the building or the infrastructure but also the lives of people by reducing the potential for accidents or collapse.

6. Improved Performance in Stressful Situations

Concrete routinely endures stresses such as high loads, vibrations, and thermal expansion. When a concrete member receives failure mitigation protection, the stresses can exacerbate the corrosion, which can lead to premature failures.

Corrosion inhibitors act to protect the bond between steel reinforcement and concrete in stressful situations, which helps maintain stability/perform under conditions of stress.

Corrosion inhibitors can also be especially useful in structural elements of the infrastructure industry, such as bridges, industrial plants, and transport infrastructure, which exhibit high mechanical and environmental loads.

7. Compatibility with Other Admixtures

In the development of modern concrete, it is often the case that several other admixtures need to be added simultaneously for the concrete to possess the desired characteristics of workability, April strength, or acceleration. Fortunately, corrosion inhibitors are typically highly compatible and can be used with other admixtures.

As a result, they can be easily integrated into client mix designs without disturbing the effectiveness of a different admixture. At Sakshi Chem Sciences, the corrosion inhibitors produced are designed to work effectively and synergistically with a variety of concrete additives to help your client achieve strength, durability, and performance.

8. Cost-Effectiveness

On the surface of it, introducing corrosion inhibitors into a concrete design might look like an additional expense; however, the future cost savings far outweigh the additional upfront expense.

By reducing maintenance and repair costs, minimizing downtime, and extending the service life of structures, corrosion inhibitors provide exceptional value.

For asset owners, developers, and contractors, this translates to significant financial savings over the project lifecycle.

Furthermore, by reducing the environmental impact of repairs and replacements, they support sustainable construction practices, making them both an economical and eco-friendly choice.

Conclusion

The use of Corrosion Inhibitors for the Durability of Concrete is no longer optional; it is essential for ensuring the longevity, safety, and sustainability of modern construction.

From protecting steel reinforcement to enhancing performance under stress and reducing life-cycle costs, corrosion inhibitors provide unmatched benefits across all types of projects.

At Sakshi Chem Sciences Pvt. Ltd., we are proud to be at the forefront of developing advanced corrosion inhibitors and other high-performance construction chemical solutions.

With our world-class R&D, rigorous quality standards, and decades of experience, we help builders, engineers, and contractors achieve stronger, safer, and longer-lasting structures.

Choose Sakshi Chem Sciences, because durable construction begins with trusted solutions.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.