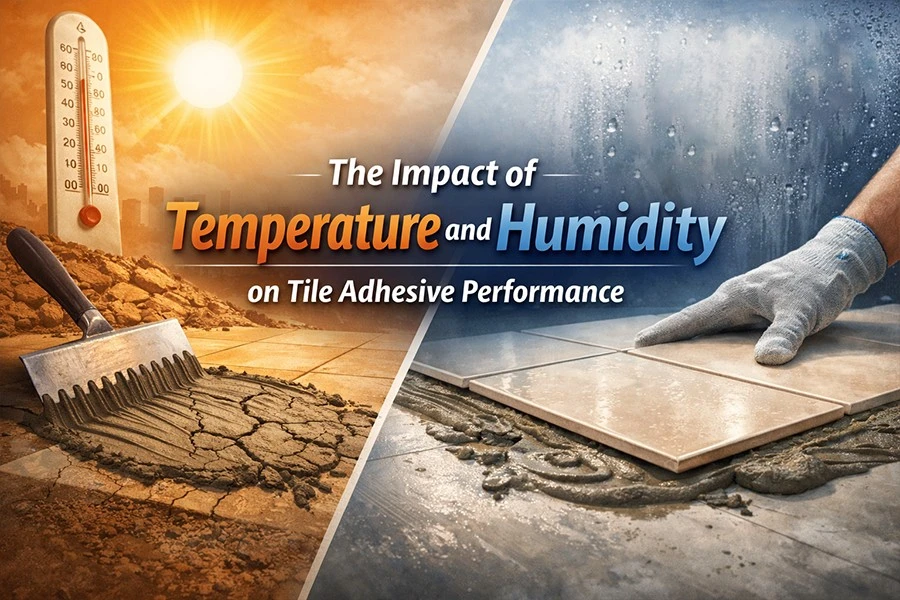

Tile installation may appear to be easy, but for a long-term, successful installation, there is much more to consider than just the surface.

One of the most overlooked aspects of tile installation is that the environmental conditions when the tile adhesive is to be applied and cured have a huge impact on whether or not even the best quality adhesive will perform as intended when temperature and humidity requirements are not taken into account.

Table of Contents

To ensure long-lasting tile installations that will not crack or come apart, contractors, builders, and project managers need to properly understand how temperature and humidity affect the performance of tile adhesives.

The environmental conditions will directly affect the curing of the adhesive, but also the bond strength and overall success of the installation.

Therefore, it is just as important to consider the environmental conditions as it is to consider the materials selected and how they are installed.

Why Environmental Conditions Matter in Tile Adhesive Performance?

Tile adhesives rely on controlled chemical reactions and moisture balance to achieve proper bonding. Cement-based and polymer-modified adhesives need sufficient time, correct hydration, and stable conditions to develop strength. Temperature and humidity influence:

- Open time and workability.

- Curing speed and hydration.

- Bond strength between tile and substrate.

- Long-term durability and resistance to cracking.

Ignoring these variables often leads to failures such as tile debonding, hollow sounds, or premature cracking.

Impact of Temperature on Tile Adhesives

Ideal Temperature Range

Most tile adhesives perform best when applied between 10°C and 30°C (50°F–85°F). Within this range, hydration and polymer film formation occur smoothly, allowing the adhesive to achieve full strength.

High Temperature Conditions

High temperatures can seriously affect tile adhesive performance if not managed properly.

Key challenges include:

- Rapid water evaporation, reducing open time.

- Surface skinning, preventing proper tile embedding.

- Incomplete hydration, leading to weak bonding.

- Increased shrinkage, which may cause cracks.

When adhesives dry too quickly, they do not get enough time to chemically bond with the tile and substrate. This often results in poor adhesion and reduced durability.

Best practices in hot conditions:

- Work during early morning or evening hours.

- Dampen substrates lightly before application.

- Avoid applying adhesive in direct sunlight.

- Use adhesives formulated for extended open time.

Low Temperature Conditions

The unique problems presented by cold temperatures when applying tile adhesives can be categorized into three general areas; the first is the slower curing time and the delayed development of strength

Second, the setting time will be longer than anticipated thus delaying the time frame required to grout the tiles; thirdly; any tiles that have been installed will have a risk of experiencing temperatures below 5 degrees Celsius

Any water within the tile adhesive that has frozen will expand and disrupt the bond structure and cause an irreparable loss of performance for the tiles.

Some common practices to follow when working in cold conditions:

- Keeping the temperature of the ambient environment above recommended limits.

- Utilizing fast-setting or cold-weather-compatible adhesives.

- Protect newly installed tile from being exposed to frost while curing.

Thermal Movement After Installation

The expansion and contraction of tiles and their substrates due to fluctuations in temperature after installation will pose significant stresses upon the installed tile and substrate with rigid tile adhesives; therefore, the chances of cracking or debonding will be greatly increased.

In comparison, a flexible polymer modified adhesive will provide much greater performance in an application with a high frequency of temperature changes.

Moisture and Its Effects on the Performance of Tile Adhesives

The ideal range of relative humidity for the application of tile adhesives and curing of tile is between 40%-70% relative humidity and when the humidity level is outside of this range, there will be a moisture imbalance which will affect the tile adhesive.

High Humidity Conditions

In high relative humidity, the evaporation and curing process is prolonged.

Problems associated with high relative humidity:

- Longer curing time

- Delayed grouting schedule.

- Increased risk of moisture being trapped.

- High probability of mold growth and/or efflorescence.

Excess moisture in the substrate, which is prevalent in high-humidity areas, will lead to a weak bond if the excess moisture is not addressed before the installation of tiles.

Best practices in high humidity:

- Ensure substrates are dry and moisture-tested.

- Improve ventilation during indoor applications.

- Allow extended curing time before grouting.

Low Humidity Conditions

Low humidity causes adhesives to lose moisture too quickly.

Challenges include:

- Rapid drying and reduced workability.

- Weak internal bonding.

- Surface crusting before tile placement.

This imbalance can compromise the adhesive’s internal strength, even if the surface appears properly set.

Best practices in low humidity:

- Lightly moisten substrates before application.

- Avoid strong air drafts during curing.

- Use adhesives with better water retention.

Environmental Considerations for Different Applications

Indoor Installations

Indoor projects allow better control of temperature and humidity. Proper ventilation, dehumidifiers, or air conditioning can help maintain ideal conditions.

Outdoor Installations

Outdoor tiling faces direct exposure to sunlight, rain, wind, and temperature fluctuations. Weather-resistant and flexible adhesives are essential, along with careful scheduling based on forecasts.

Best Practices to Manage Temperature and Humidity Effects

- Monitor site conditions using thermometers and hygrometers.

- Store tile adhesives in shaded, dry, and climate-controlled areas.

- Use clean, room-temperature water for mixing.

- Follow manufacturer guidelines for water ratio and open time.

- Adjust work schedules according to weather conditions.

Why Quality Tile Adhesives Make a Difference?

While environmental control is important, adhesive formulation also plays a major role. High-quality tile adhesives are engineered to perform consistently across varying climates, offering improved flexibility, water retention, and bonding reliability.

At Sakshi Chem Sciences, construction chemical solutions are developed with a deep understanding of real-world site conditions. Advanced additives and strict quality control ensure that tile adhesives perform reliably even when temperature and humidity fluctuate within practical limits.

Conclusion

The Impact of Temperature and Humidity on Tile Adhesive Performance cannot be overstated. Environmental conditions directly influence curing behavior, bonding strength, and long-term durability.

By understanding these factors and applying best practices, installers can avoid costly failures and deliver professional, long-lasting tile installations.

Successful tiling is not just about choosing the right adhesive—it’s about using it under the right conditions. With proper planning, quality materials, and environmental awareness, tile installations can withstand time, climate, and daily use with confidence.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.