Tile adhesive is no longer just a quick alternative to cement mortar, but has become a form of construction solution that has evolved from being a simple material designed to fix tile flooring and wall tiles.

The construction industry now requires products that are not limited by older forms of construction due to increased use of modern building designs, heavy-weight tiles, the requirement for more complex designs and a long life span. Tiles are an example of the new demand for these types of products in the construction industry.

Table of Contents

Sakshi Chem Sciences has always strived to make construction products that not only perform well, but also exceed expectations in all respects regarding bonding, flexibility and durability.

The construction industry’s reliance on advanced formulae has resulted in achieving results that were previously impossible to accomplish with cement-sand mortar.

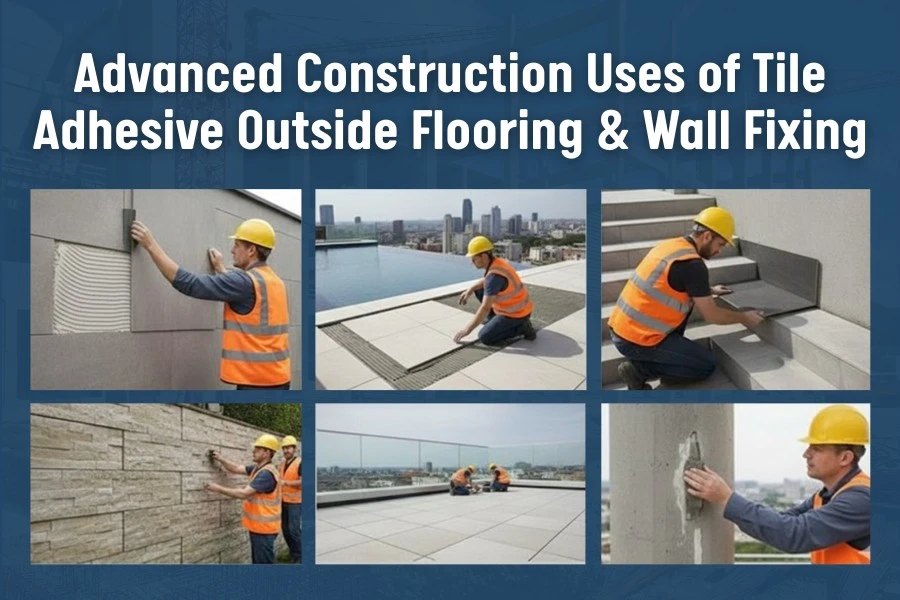

The following Guide will provide a detailed overview of Advanced Construction Uses of Tile Adhesive. These uses go beyond merely fixing tile.

Why is Tile Adhesive Becoming More Important to the Industry?

While cement-sand mortar may continue to be used in some parts of the world, it is apparent that cement-sand mortar has several disadvantages compared to tile adhesive:

- It bonds poorly with modern low-absorption tiles.

- It provides little protection from shrinkage and cracking.

- There is no flexibility to accommodate movement in structures.

- It does not offer a good level of waterproofing.

- Tile adhesive is manufactured using a mixture of cement, polymers, additives, and graded sand.

This combination ensures predictable performance, strong adhesion, and long-term durability that modern construction projects require.

Key benefits include:

- Higher bond strength for heavy tiles and stones.

- Flexibility to handle thermal and structural movement.

- Water-resistant and moisture-proof properties.

- Faster and cleaner application.

- Ability to work on a wide range of surfaces, including tile-on-tile.

These features make Tile Adhesive indispensable for modern buildings, infrastructure, and high-design interior spaces.

1. Exterior Facades and Elevation Cladding

Tile adhesive has become a significant part of modern Building Construction in the installation of Façades. It is used in the installation of ceramic, porcelain, stone, and decorative panels, and all require tile adhesive for strong bonding to provide continued performance over an extended period of time.

As mortar cannot withstand the External stresses caused by temperature changes, Polymer-Modified Tile Adhesives are manufactured specifically to accommodate movement and prevent separation.

Winter Adhesive’s Preference:

- Superior Adhesion for Vertical Graphic Work.

- Weather & UV Resistance.

- Greater Flexibility For Thermal Sediments.

- Lightweight In Comparison To Heavily Mortared Floors.

Today, tile adhesive is not just an option for modern elevations; it is necessary!

2. Submerged Surfaces & Installations

Tile Damage is Most Commonly Caused by the presence of high levels of Water in these environments. As a result, Ordinary mortar can absorb moisture and Couple with the natural expansion and contraction of Mortar, leading to the detachment of the tile.

Tile Adhesives Create a Strong, Waterproof, Inert bond, making it the best option for use in all of the following applications:

- Swimming pools.

- Decorative Fountains.

- Jacuzzi Style Baths.

- Outdoors Terraces & Balconies.

- Water Storage Facilities.

Preventing the continued flow of water through water storage systems will fortify water storages & installations. The advantage of tile glue in this case will also extend the life of tiled installations.

3. Tile-on-Tile Renovation Without Demolition

Removing old tiles takes time, labor, and money during a renovation. Tile Adhesive provides an alternative to this problem: tile-on-tile fixing means that new tiles may be installed directly over existing ones.

Homeowners and contractors can benefit from the use of this product as it eliminates the need to remove existing tiles in order to install new ones. Benefits of using Tile Adhesive include:

- No need for demolition.

- No dust or debris.

- Faster completing of projects.

- Reduced labor costs.

- Compatible with ceramic, vitrified and natural stone tiles.

Using Tile Adhesive allows for the completion of renovation projects in less time and with a clean process.

4. Fixing Large-Format Tiles, Slabs and Vitrified Panels

The increased use of large-format tiles (i.e., tiles that are larger than the standard 18″x18″ format), slabs made from full body vitrified tile and large panels made from porcelain (typically imported marble alternatives) is becoming more common in modern residential and commercial design.

These materials are dense and heavy and therefore require a stronger bond than what can be provided using mortar. Tile adhesive provides the following to ensure the installation of these materials is a success:

- No Slip or Movement on Verticals.

- Coverage to Eliminate Hollow Spots.

- Proper Bonding for Heavily Loaded Materials.

- Crack Resistant Under Load.

5. Decorative Stone and Interior Cladding

Decorative stone such as marble, granite, sandstone, etc., is often used to create focal points in interior spaces such as lobbies, lift areas, and living rooms. Tile Adhesive is an excellent solution for these applications because it offers a number of benefits:

- Strong vertical adhesion.

- Compatibility with heavy natural stones.

- Colour-stable formulations that prevent staining.

- Reduced risk of stone detachment.

From rustic interiors to high-end marble cladding, tile adhesive ensures elegance with safety.

6. Industrial and Commercial Installations

When constructing large buildings, including shopping malls and airports, Hospitals and kitchens require many types of material to provide superior strength under extreme amounts of:

- Heavy Foot Traffic.

- Heavy Loads.

- Extreme Temperature Fluctuation.

- Exposure to Chemicals for Cleaning.

- Moisture Exposure.

Tile Adhesive is the ideal solution for providing the durability and long-lasting performance required in these buildings. Tiles will stay secure in these applications even in areas that are regularly vibrated or subjected to constant cleaning.

7. Underfloor Heating Systems / Temperature Manifold Systems

In a more advanced building system that uses under floor heating, mortar cannot support the temperature-induced movement and expansion forces on the tile and will ultimately break.

Tile Adhesive, on the other hand, provides excellent support and maintains a secure bond to the tile even with fluctuating temperature.

Examples:

- Modern smart homes.

- Luxury Hotel Flooring.

- High-tech Office Space.

Latest technology of how wide-ranging tile adhesives have become.

8. Ramps / Staircases and Curved surfaces

The installation of ramps and/or curved surfaces is much more exacting than flat surfaces, as there is an added force of gravity and continual movement to consider.

Tile Adhesive provides an enormous amount of non-slip support for the tile and provides the necessary shaping and alignment correct for installing tiles.

Uses:

- Stairs in public places.

- Walkways through shopping malls.

- Curved design of lobbies.

- Ramps in parking garages.

Tile Adhesive provides excellent support to hold the tiles in place under extreme pressure.

Why Sakshi Chem Sciences Tile Adhesives Stand Out?

With decades of experience in construction chemicals, Sakshi Chem Sciences offers high-performance tile adhesives engineered for:

- Strong bonding on diverse surfaces.

- Enhanced flexibility.

- Water resistance for wet areas.

- High durability under load and weather changes.

- Long working time for convenient application.

Our formulations support modern construction requirements while ensuring reliability, safety, and longevity.

Conclusion

The construction world has changed, and so have its demands. Tile adhesive is no longer limited to basic tile fixing, it now plays a crucial role in façades, renovations, decorative installations, water bodies, high-load areas, and more.

Choosing advanced tile adhesive technology results in:

- Stronger structures

- Faster installation

- Reduced maintenance

- Long-lasting durability

With Sakshi Chem Sciences leading innovation in construction chemicals, the future of tile installation is efficient, versatile, and built to last.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.