Choosing the Right Silica for Performance, Stability, and Strength

Silica is one of the most widely used materials in a range of industries, including adhesives and sealants, coatings, electronics, pharmaceuticals, and construction.

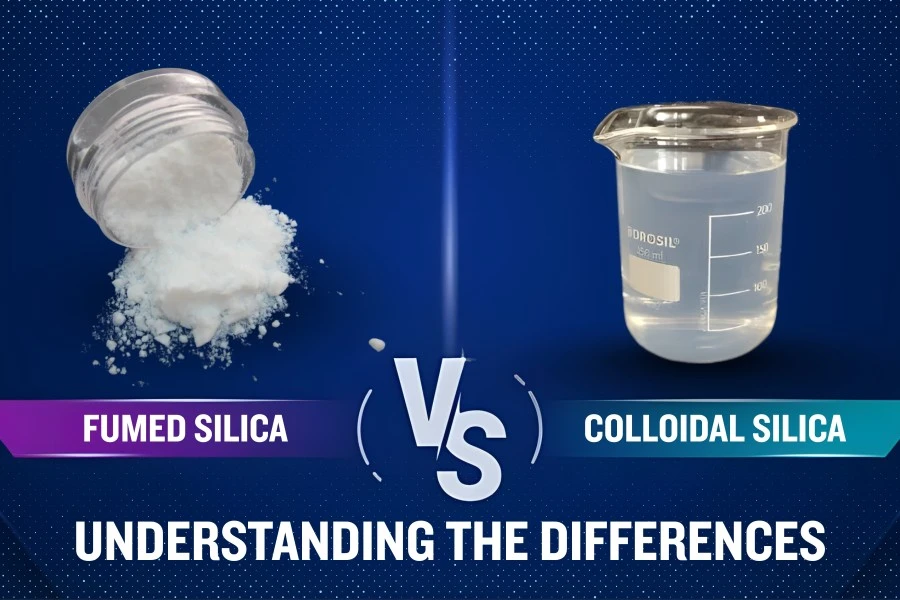

Not all silica has the same properties, however. For example, while fumed silica and colloidal silica may sound similar, these two types of silica have distinctly different characteristics.

Table of Contents

It is essential for manufacturers, R&D teams, and formulators to understand the significant differences between fumed silica and colloidal silica in order to identify the appropriate ingredient for controlling viscosity, reinforcing, increasing stability, or improving surface quality.

At Sakshi Chem Sciences, we work with coatings, construction, and chemical industries to assist manufacturers in selecting additives that result in the production of stronger, more stable, and efficient formulations. This guide outlines the variations between these two silica types in a plain and practical manner.

1. Fumed Silica

Fumed silica (also referred to as pyrogenic silica) is considered to be an ultra-fine, high-purity, fluffy powder form of silica. It is manufactured by a flame-based process called flame hydrolysis.

How Fumed Silica is Manufactured?

Silicon tetrachloride is combusted in a hydrogen/oxygen flame. Once the silicon tetrachloride vapor has cooled, an extremely fine powder of silica (amorphous in nature) is formed.

Fumed Silica’s Physical Characteristics

The fumed silica has a very large surface area.

Fumed silica’s chain-like particle structure (amorphous).

Ultra-light, low bulk density.

Available in hydrophilic and hydrophobic grades.

Where It’s Used

Fumed Silica is used primarily as a performance additive for:

- Increases viscosity and thixotropy.

- Prevents Settling and Sagging.

- Provides Stability and Controlling Viscosity.

Typical Uses

- Paint and Coatings.

- Silicone Sealants and Adhesives.

- Printing Inks.

- Cosmetics and Personal Care Products.

- Gentle Oils.

- Greases and Lubricants.

Fumed Silica provides strong, stable and controllable rheology with low dosages.

Colloidal silica is a stable suspension of spherical silica nanoparticles suspended in a liquid (water).

2. How is Colloidal Silica Created?

Colloidal Silica is produced when sodium silicate is treated with acid under controlled conditions. Thus, silica is produced that remains suspended in a liquid without settling.

Colloidal Silica Is Characterized By

- Spherical Particle Size.

- Narrow Particle Size Distribution.

- High Purity.

- Excellent Suspension Stability.

- Water-Based.

Typical Uses For Colloidal Silica

Colloidal silica is typically selected when:

- A Liquid Form.

- Smooth Finishes.

- Uniform Surface.

Typical Application Uses: Concrete Densifier/Durable Hardener; Polishing Slurries (Electronics or Optical); High Performance Coatings; Investment Casting Binders; Catalysts.

The primary benefit of Colloidal Silica is that it provides a consistently uniform and dense material without the aggregation of particles occurring.

3. Fumed Silica vs Colloidal Silica

Fumed and colloidal silica are similar materials (both are silicon dioxide), but that’s where their similarities end. Below are the clearest ways to identify each material.

| Feature | Fumed Silica | Colloidal Silica |

| Form | Fine powder | Liquid suspension |

| Particle Shape | Chain-like, branched | Spherical |

| Main Use | Thickening, thixotropy | Surface densification, polishing |

| Viscosity Control | Excellent | Moderate |

| Stability in Water | Requires dispersion | Highly stable |

| Best For | Coatings, adhesives, cosmetics | Polishing, concrete, casting |

In short:

Fumed silica is for rheology. Colloidal silica is for densification and polishing.

4. Understanding Silica Fume (Secondary Keyword): Not the Same as the Two Above

Silica fume is often confused with two other products – fumed silica and colloidal silica. However, these are three distinctly different materials that all contain silica, and they have completely different applications, structures, and purposes.

Silica fume is a by-product created during the production of silicon metal/ferrosilicon in electric arc furnaces, and consists primarily of ultra-fine particles that can be highly reactive with cement in concrete.

The primary use of silica fume in construction is as a pozzolanic material because of its very fine particle size. Silica fume serves an important role in creating high-performance concrete by:

- Increasing the compressive strength of concrete

- Increasing impermeability to water (waterproofing)

- Decreasing the chance of chloride penetration (chloride attack)

- Increasing the durability of concrete in harsh environments

Silica fume has other uses besides being used in high-performance concrete, such as for bridge/tunnel/dam construction, industrial floors, marine structures, etc.

As stated above, all three products contain silica, but each serves its own specific purpose, has its own structure, and is used in very different ways.

5. Key Applications Breakdown

Fumed silica is most effective for:

- Increasing sag resistance of coatings.

- Increasing spreadability of adhesives & sealants.

- Decreasing the tendency of pigments to settle out.

- Increasing the viscosity of gels & creams.

- Increasing the stability of resins.

Colloidal silica is most effective for:

- Polishing semiconductors (the CMP slurry process).

- Densifying concrete floors.

- Investment casting molds.

- Increasing chemical resistance in coatings.

Silica fume is most effective for:

- Concrete reinforcement.

- Decreasing permeability in concrete.

- Increasing the early strength of concrete.

- Increasing the durability of concrete in harsh environments.

In other words, each silica product has its own unique application and cannot be replaced by the other two.

6. Advantages & Limitations

Fumed Silica – Advantages

- Excellent rheology control.

- Low dosage needed.

- Works in solvent and water-based systems.

- Improves stability and anti-settling.

Limitations:

- Difficult to disperse without proper mixing.

- Can increase formulation cost.

Colloidal Silica – Advantages

- Extremely stable dispersion.

- Produces smooth, dense finishes.

- Ideal for precision applications.

- Water-based and safe to handle.

Limitations:

- Not suitable for solvent-only systems.

- Higher moisture content.

Silica Fume – Advantages

- Strengthens concrete significantly.

- Reduces cracks and permeability.

- Enhances long-term durability.

Limitations:

- Increases water demand in concrete.

- Needs strong mixing controls.

7. How Sakshi Chem Sciences Helps You Choose the Right Silica?

Sakshi Chem Sciences provides over 20 years of experience, state-of-the-art R&D, and a focus on quality assurance and standards around the world to assist its customers with technical guidance in:

- Selecting the best grade of silica

- Optimizing formula

- Improving product consistency and stability of rheology

- Enhancing the performance of coatings and concrete

No matter what industry you work in (construction chemicals, coatings, adhesives, or high-tech materials), we help with the selection of an appropriate additive for your formulation.

Conclusion

The understanding of the differences between fumed silica, colloidal silica, and silica fume is critical to producing a high-performance, stable, and cost-effective formulation.

Fumed silica will improve viscosity, texture, and flow properties.

whereas colloidal silica will improve surface finish, density, and stability.

Silica fume strengthens concrete and improves the durability of concrete products.

These three materials play distinct roles in their respective industries, and the use of the correct material can dramatically enhance the performance and reliability of products manufactured.

At Sakshi Chem Sciences, we support manufacturers’ decision-making processes by providing the necessary technical expertise, the highest quality materials, and continuing commitment to innovation.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.