When you open a canister of paint, you expect it to be smooth and creamy. You would not expect to find any trapped air bubbles or foam.

If you have recently purchased a new or reformulated water or solvent-based paint, you may have noticed that it created foam during manufacturing, during mixing, and during application. This is why defoamers are important for paints and coatings.

Table of Contents

Although foam may not seem harmful to the average person, it can actually create a significant amount of contamination and problems affecting the application quality, final finish, drying time, and long-term durability of the paint or coating.

Controlling or eliminating foam as much as possible is one of the main things that manufacturers and applicators need to do to produce a quality product.

What are defoamers used for, and how do they work in paints and coatings?

Defoamers are special additives that are specifically designed to both reduce and eliminate foam from liquid materials. They help to eliminate air bubbles that can form in liquid paint and coatings, created during:

- High-Speed Mixing

- Pumping and Filing

- Brushing/Rolling/Spraying

- Packaging

- Storing

A good defoamer will do two things:

1. Lower the Surface Tension of the Liquid

By doing this, the defoamer inhibits the ability of bubbles to form easily.

2. Destroy Bubbles That Already Exist

A defoamer destabilizes bubbles and allows them to collapse almost instantaneously if the liquid contains foam or entrapped air.

In simple words:

Defoamers ensure that paint stays smooth, spreadable, and visually flawless.

Why Foam Is a Big Problem in Paint & Coating Systems?

Foam has the potential to cause issues throughout the manufacturing process as well as with the final appearance of any given coating. Some of the common issues created by foam are:

• Fish-Eyes and Craters

These surface imperfections are caused when air becomes trapped under the coating.

• Poor Gloss

Foam creates a dull surface because it disrupts the way light reflects off the coating surface.

• Poor Leveling

Foam does not allow paint to properly spread evenly.

• Pinholes & Micro-Void

Both pinholes and micro-voids can diminish the coat’s protective qualities.

• Inconsistent Colour

Foam interrupts the even distribution of pigment throughout the coating.

• Slower Drying Time

More air means it takes longer for a surface to level.

These defects are not acceptable for waterproof coatings, anti-corrosive paints, and construction coatings, and are why formulations cannot perform well without a quality defoamer.

Different Types of Defoamers Utilised in Paints and Coatings

Different types of coatings require different foam-control technologies. The most common defoamers used include:

Silicone-Based Defoamers – Extremely effective, ideal for high-viscosity systems, and for reducing foam drastically. Silicone-based defoamers provide excellent long-lasting defoaming and are widely used in industrial coatings.

Mineral Oil-Based Defoamers – Cost-effective, suitable for primers, emulsions, and economical formulations.

Polymer-Based Defoamers – Good water-based compatibilities for coating systems without impacting gloss or clarity.

Wax-Based or Hybrid Defoamers – Commonly used for high-solid systems or specialised coatings.

At Sakshi Chem Sciences, we manufacture and supply advanced defoaming solutions that suit both budget-friendly formulations and premium high-performance coatings.

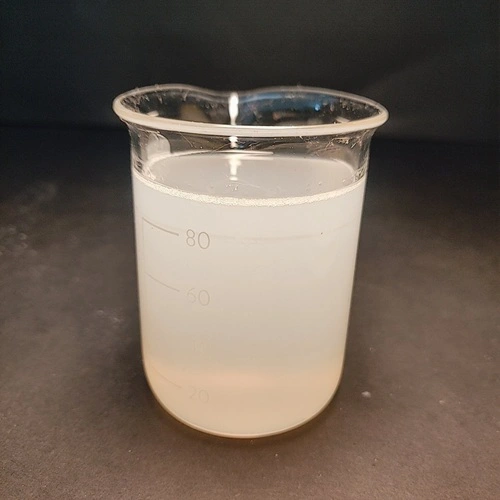

One such product is our Addage defoamer liquid, engineered to deliver fast, stable, and long-lasting foam suppression across a variety of paint and coating systems.

Introducing Addage Defoamer Liquid

Engineered to Be Current for Paint and Coatings Engineering.

With Addage Defoamer Liquid, manufacturers have the ability to control their foam-related issues.

Here are some Advantages of using Addage Defoamer Liquid:

- Fast Breaking Bubbles.

- Can be used in both solvent and water-based systems.

- Increases leveling, finish, and smoothness.

- Compatible with the majority of emulsion types and binder types.

- Heat stable and able to function in the widest temperature ranges.

- Has no detrimental effect on the gloss or color development.

- Elimination of micro-foam formulation during long term storage.

- Effective at very low dosage levels.

Manufacturers appreciate Addage for reducing defects, creating longer-lasting coatings, and providing consistent manufacturing alignment. Applicators value the ability to apply with a more even film thickness and the premium appearance of the finished product.

Where Are Defoamers Used? (Industry-Wide Application)

The use of Defoamers for Paints and Coatings is applied to many different products:

1. Architectural Coatings

Emulsions for interior and exterior use; primers; putties; texture; finish.

2. Industrial & Protection Coatings

Marine, high solids, anti-corrosion.

3. Waterproofing & Constructing Coatings

Elastomeric, acrylic, cementitious roof coatings; waterproofing.

4. Printing Inks

Helps eliminate bubble formation during high-speed printing.

5. Adhesives & Adhesives

Bubble elimination = stronger bond and adhesion.

6. Wood Coatings

Lacquers and clear coat sealers.

7. Specialty Coatings

Heat Resistant, Chemical Resistant, Auto Finish.

Wherever air and mixing meet liquid chemistry, a defoamer becomes essential.

How to Select the Right Defoamer for Your Paint or Coating Formulation?

When selecting a defoamer, the process should not be considered an arbitrary selection, but rather, researched and fully understood through application.

Evaluating the following areas is critical to your decision-making process:

1. The Type Of System You Are Creating

Will it be water-based or solvent-based?

2. The Compatibility of Your Binder

Will you be using an acrylic, styrene-acrylic, PU or epoxy?

3. The Conditions Under Which You Will Be Processing

When you use high-speed dispersion to mix your material, it will produce foam faster than using low-speed mixing.

4. The Gloss Level Required

Certain defoamers may cause your paint to look dull; therefore, it is important to select wisely.

5. The Stability Of Your Defoamer

A good quality defoamer will provide you with a stable product for several months.

At Sakshi Chem Sciences, we are focused on providing more than just effective products; we also provide our customers with the technical expertise they need to help select the best defoamer for their needs.

Conclusion

Foam is a small problem, but it is also a major issue for paint and coating systems. From decreased performance and surface defects to increased production costs, uncontrolled foaming can affect both paint performance and production efficiency.

Using the appropriate defoamer for both paints and coatings promotes:

- Smooth, even finishes.

- Consistent quality.

- Greater durability.

- Improved ease of handling.

Manufacturers of decorative paints, waterproof coatings, industrial coatings, and specialty chemicals can successfully remove the foam issue from their production process and maintain their business successfully, due to advanced technologies such as Sakshi Chem Sciences Addage Defoamer liquid and the support of our Technical Support group.

Whether you are producing decorative paints, waterproof coatings, industrial coatings, or specialty chemicals, selecting the appropriate defoamer is critical to your success. We are here to assist you in getting it done right!

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.