Starch ether and cellulose ether are two of the most used modified natural polymers in construction, pharmaceutical, food, and other industries.

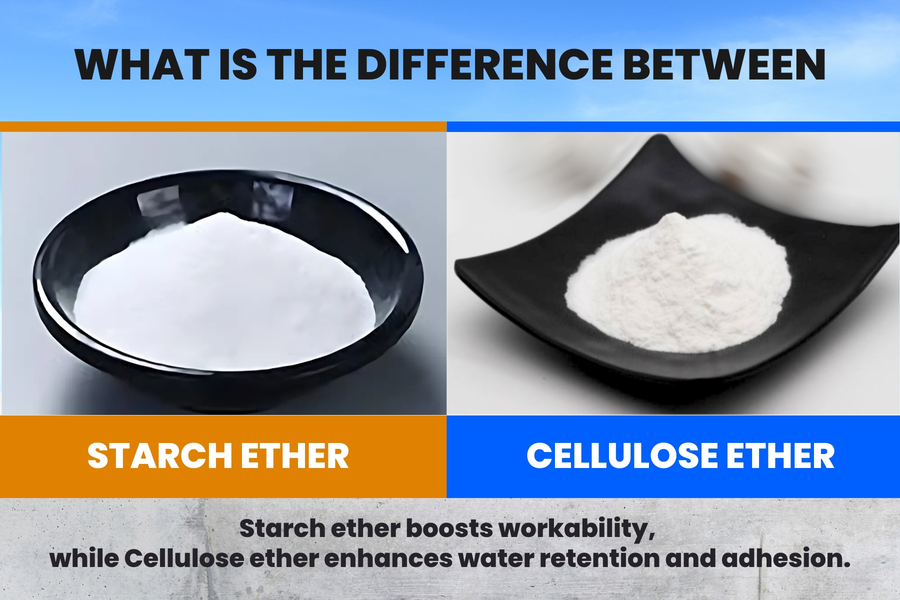

Although starch ether and cellulose ether belong to the group of water-soluble polymers, they differ in their chemical structure, sources, properties, functions, and applications.

The blog delineates a difference between starch ethers and cellulose ethers, based on other aspects like chemical structure, sources of source of source of preparation of chemically, functional and using manner, market trends, and uses.

Table of Contents

1. Chemical Structure

Starch Ether:

Starch ether is a carbohydrate polymeric compound consisting of glucose residues. The modification involves the replacement of the hydroxyl (–OH) groups on the glucose units at various positions or external ether substitutions (like ethyl, hydroxypropyl, or methyl groups).

Carbohydroxyl modification allows starch to have significantly broad potential applications owing to the modification of its physiochemical properties.

Starch comprises amylose (a linear polymer) and amylopectin (a branched polymer). Modification to form starch ether alters these molecules and provides desired attributes, such as water solubility and thickening.

Cellulose Ether:

Cellulose ether is obtained from cellulose, the most naturally abundant polymer found in plant cell walls. Cellulose ether is produced from cellulose similarly to starch ether when hydroxyl groups attached to glucose units of cellulose are replaced by ether substituents.

The ether substituents in cellulose ether may be methyl, hydroxyethyl, hydroxypropyl, or other substituents. In that way, the modification renders cellulose a more water-soluble polymer and enhances its ability to interact with other materials.

Cellulose is made up of very long linear chains of glucose units; modifications in cellulose ether take place along these chains, thus influencing the final structure and properties of the cellulose ether.

The degree of substitution (DS) and ether functionality act as factors regulating the solubility, viscosity, and other functional performance.

2. Sources

Starch Ether:

Starch is made from plant-based raw materials like corn, potatoes, wheat, and rice. Starch ether is obtained by chemical modification of starch extracted from these plants. Corn starch has gained considerable commercial importance due to its availability and relatively cheap cost.

Starch is a renewable and biodegradable material, making it an environmentally friendly source for making starch ethers. However, chemical processing in the production of starch ether in many instances compromises the environmental integrity of the end product.

Cellulose Ether:

Nature of cellulose ether, on the other hand, is obtained from cellulose, in general derived from wood pulp, cotton, or other plant fibers. Cellulose is a matrix of the plant cell wall, and the plant material has to be broken down to obtain cellulose fibers.

Again, cellulose is a renewable resource, and that makes it a highly widespread raw material, especially in paper manufacturing. Cellulose ethers are produced from chemical treatment of cellulose to furnish it with solubility and functionalities.

3. Physicochemical Properties

Starch Ether:

Modified properties of starch ethers that vs those of the native starch include:

Solubility: Starch ethers, with particular reference to the degree of substitution, have various other degrees of water solubility, thus allowing for formulation of various end-products. An example being hydroxypropyl starch ethers, where their solubility in cold water is superior when compared to other classes of starch ethers.

Viscosity: Starch ethers are effective thickeners and form gels, emulsions, or viscous solutions, depending on the degree of substitution and specific ether group used.

Thermal stability: Starch ethers have better thermal stability than native starch and can therefore be suitable for protecting from thermal degradation.

Biodegradability: Since starch ether is derived from natural starch, it is biodegradable; this makes it an eco-friendly choice for uses with a minimal environmental impact.

Cellulose Ether:

Cellulose ethers revealed several improved properties because of modification process:

Water solubility: Cellulose ethers such as hydroxyethyl cellulose (HEC) and methyl cellulose (MC) are quite soluble in water, which considers an advantage for the binding and thickening capabilities in various formulations.

Viscosity: Cellulose ethers are widely used for their excellent thickening and stabilizing properties. They can increase the viscosity of aqueous solutions, suspensions, and gels.

Thermal stability: Like starch ethers, cellulose ethers also demonstrate good thermal stability, a development that is important for applications pertaining to construction materials and pharmaceuticals.

Inertness: Cellulose ethers are, on the whole, chemically inert and nontoxic, making them suitable for use in food and pharmaceutical products.

4. Functions and Applications

Starch Ether:

Starch ethers are mainly used in:

Construction and mortar: In construction, starch ethers act as thickening agents in cement products, thereby improving workability and water retention capacity. Hydroxypropyl starch ether is popularly used in mortar, plaster, and tile adhesives.

Food Industry: Starch ethers find use as thickening agents, gelling agents, and stabilizers in processed foods such as sauces, soups, and dressings.

Pharmaceuticals: Starch ethers are widely employed in the pharmaceutical industry as excipients in tablet formulations for controlled drug release; they are also used as binders in the manufacture of pills.

Cosmetics: Starch ethers are important in cream, lotion, and sham-washing products, contributing to improved texture and viscosity of the products.

Cellulose Ether:

Cellulose ethers have a wide range of applications in various industries:

Construction: Cellulose ethers (that is, hydroxyethyl cellulose and methyl cellulose) are used to provide improved workability in cement and plaster products. They are also used in formulating grout, adhesives, and tile bonding agents.

Food industry: Much like starch ethers, cellulose ethers are used as thickeners and stabilizers in food products. Most often seen in ice cream, dairy products, and salad dressings.

Pharmaceuticals: In pharmaceuticals, cellulose ethers are widely used in tablet coatings, drug delivery systems, and controlled-release formulations.

Cosmetics and personal care: Because cellulose ethers allow for smooth texture, they are popular in cosmetics where they may add thickening and emulsifying characteristics in lotions, shampoos, and creams.

5. Preparation Method

Starch ether:

Starch ether is typically prepared in several steps:

Esterification/Etherification: Starch is treated with etherifying agents such as propylene oxide or ethyl chloroformate using sodium hydroxide.

Neutralization: After etherification, the product is neutralized to remove any excess alkali.

Purification: The purified starch ether is the product after the removal of all by-products, rendering it usable in accordance with given specification.

Cellulose Ether:

Cellulose ether is prepared through etherification, which basically consists of:

Activation: The cellulose fibers are brought into contact with an alkali solution (such as sodium hydroxide) customarily for activating the hydroxyl groups that appear along the cellulose chain.

Reactions of Etherifying Agents: The activated cellulose is then reacted with etherifying agents under controlled conditions, such as methyl chloride, ethylene oxide, or propylene oxide.

Neutralization and purification: Polymers are typically neutralized and purified to rid them of residual chemicals.

6. Market Demand and Development Trend

Starch Ether:

The demand for starch ether is increasing, especially in the construction, food, and pharmaceutical industries. The ever-growing inclination towards green and renewable building materials increases the acceptability of starch ethers.

These are biodegradable and provide a renewable alternative to synthetic polymers. Also, steady growth in the pharmaceutical domain is triggering a demand for starch ethers, which are used as excipients for drug formulations.

Cellulose Ether:

The cellulose ether market is anticipated to realize significant growth due to increasing application use in industries such as construction, pharmaceuticals, personal care products, and food.

The development of new cellulose ether derivatives with better properties would drive the market further.

Cellulose ether is considered an important component in the manufacture of high-quality products, which have wide applicability. The endless applications by various sectors guarantee a continued rapid growth.

Do You Fully Realize the Function of Starch Ether in Mortar?: Starch ethers are essential for the application of both plaster and mortar, either by their efficacy or performance.

In mortar design, starch ether provides mushroomy folds for workers to lay the mortar successively. It, nevertheless, provides a considerable period of workable time whereby maximum bonding and smoothing finish can be attained.

Conclusion

There exist differences between starch ether and cellulose ether in source and structure, and their differences in applications must be borne in mind when deciding which substance will be appropriate for one’s application.

With growing confidence about sustainability and greener solutions now, both starch and cellulose ethers are well poised to become key players in shaping the future of construction and pharmaceuticals.

Frequently Asked Questions

What is starch ether?

A starch ether is a modified derivative of starch in which the hydroxyl groups of starch molecule are replaced with ether groups like ethyl, hydroxypropyl, or methyl for various purposes in solubility, viscosity, and functionality.

What is cellulose ether?

Cellulose ether is a modified type of cellulose in which the cellulose hydroxyl groups are substituted by ether groups in order to give better solubility and increase its utility in various industries such as construction, food, and pharmaceuticals.

What are substituted cellulose ethers?

Substituted cellulose ethers are cellulose derivatives wherein the cellulose molecule’s hydroxyl groups have been substituted with the likes of methyl, hydroxyethyl, hydroxypropyl, etc., to achieve improved cellulose properties like solubility, viscosity, and thermal stability.

What are hydroxypropyl starch ether applications?

Common applications for hydroxypropyl starch ether are typified by its effective use as a thickener, stabilizer, and binder for construction materials, food products, and pharmaceuticals.

What is the difference between starch ether and cellulose ether?

The primary difference between the starch ether and cellulose ether is perhaps their source. Starch ethers are derived from starch and applied in industries such as construction, food, and pharmaceuticals. While cellulose ethers are derived from cellulose in construction, food, personal care, and pharmaceuticals.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.