Concrete is renowned for its excellent versatility, excellent durability and impressive strength. It is one of the most widely used building materials worldwide. Compressive strength of concrete is one of its most beneficial properties.

It is the concrete’s capacity to bear axial loads without getting damaged. Hence, to ensure optimal strength and durability of construction projects, it is extremely vital to know its inherent strength by doing strength testing of concrete.

Table of Contents

By learning about compressive strength, professional builders can ensure the concrete grade is suitable to fulfill the design requirements of any building project. This test can ensure the durability of the building, and offer excellent safety to its occupants against structural damage.

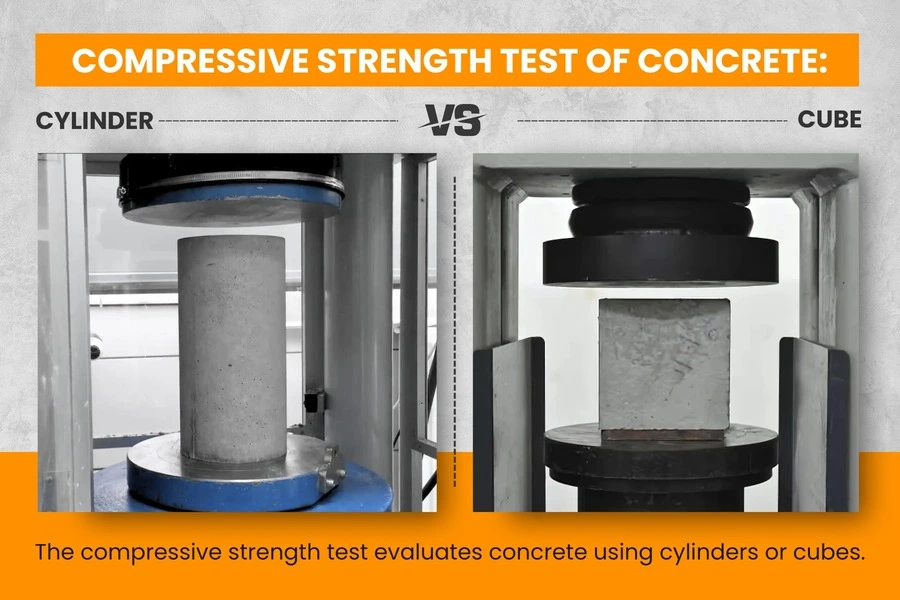

The two most popular methods used for strength testing of concrete are the ‘Cylinder’ and ‘Cube’ tests. Once you know the correct composition of the concrete, you can use concrete hardener to ensure optimal compressive strength.

In this blog, you will learn everything you need to know about compressive strength testing of concrete using the Cylinder and Cube testing methods, their individual differences, specific advantages, and their suitability for different situations.

Why Compressive Strength Testing of Concrete?

In simple words, compressive strength is any material’s capacity to bear loads on its surface without developing structural damage, such as cracks, spalling, deterioration, etc. Putting tension on any material makes it elongated, while compressing it reduces its size.

The compressive strength of concrete structures is the most crucial factor for determining the overall quantity of the concrete. Strength testing of concrete helps to decide whether the concrete mix can bear the loads expected from its design without the risk of structural weakening or physical damage.

These tests can effectively prevent structural issues, such as deformation, spalling, cracking, or complete failure of structure. Experts advise using high-quality concrete hardener to avoid cracks in concrete structures.

Besides this, strength testing of concrete also helps to find –

Best Mix Recipe

The compressive strength of concrete can help determine whether you have used sufficient proportions of building materials in the concrete mix.

Check Curing Progress

Learning about compressive strength testing of concrete helps understand whether the concrete has achieved the desired internal strength, at different stages of the construction, such as when removing the framework, and post-tensioning phase.

Ensure Optimal Safety

Knowing the specific compressive strength of concrete mixes also aligns your project with modern construction regulations and helps comply with structural safety standards.

Hence, without proper strength testing of concrete, it becomes difficult to prevent the risk of structural damage, lower project costs and meet completion deadlines too. Once you know how to create the ideal concrete mix, you will have to add an efficient concrete hardener to make the structure stronger and durable.

Compressive Strength Formula

The compressive strength for any material is measured by the load applied at the extreme point of durability, to the cross-section of the surface on which the load is applied.

Compressive Strength = Load / Cross-sectional Area

Cylinder vs. Cube Test: Key Differences

Now that you know the definition of compressive strength and the simple formula to calculate it, let’s learn the differences between the strength testing of concrete using the two most popular methods – Cylinder and Cube Tests.

The Cylinder Test for measuring concrete strength is most commonly used in North and South America, while the Cube Test has is a standard quality test in the UK, Europe and other areas of the globe.

Though both of these tests help to measure the compressive strength of concrete, the procedure, equipment and shape of specimen for testing differs significantly.

CYLINDER TEST

The cylinder test is also known by as Test Standard ASTM C39. In this, the specimen procured for testing is a cylinder measuring 100mm x 200 mm (diameter x height) / 4 x 8 inches. However, at times larger specimen may be required for cylinder test, such as measuring 150mm x 300mm / 6 x 12 inches, in the US and Canada.

Usually the specimen for Cylinder test for compressive strength testing of concrete is cast in 3 layers, with maximum 25 rods for reinforcement in every layer.

The cylinder test procedure involves pouring the concrete in cylindrical molds and letting the component cure for usually 28 days, or as specified by local standards. Next, the specimen cylinder is placed in specially designed compression machines.

These machines apply increasing amount of load to the specimen till it reaches the limit of its compressive strength, and breaks. The force at which the specimen breaks is then divided by the dimensions of the cross-sectional area. This division helps to measure the specific compressive strength of the concrete mix.

The compressive strength of concrete specimen are usually denoted in MPa or psi, by the compression machine.

CUBE TEST

The Cube Test for measuring compressive strength of concrete is also known as ‘BS EN 12390-3’. In this, the specimen taken is in the form of a cube measuring 150mm x 150mm x 150mm / 6 x 6 x 6 inches, with at least 3 layers, with each layer having 25 reinforcement rods.

The cube method for compressive strength testing of concrete involves pouring concrete into cube-shaped molds of the specified dimensions. The concrete is allowed to harden and then the specimen is removed, at least after 28 days.

Similarly to the other test, the cube test also requires placing the specimen in a compressing machine which gradually puts increasing amount of load on the concrete specimen. The machine eventually notes the level of compression the specimen was able to bear before it broke.

The same formula is also used to calculate the compressive strength, by dividing the compression with the cross-sectional area of the specimen’s surface.

Pros and Cons of Cylinder vs. Cube Test

After learning the individual procedure followed in the two tests, and the differences between the two, its time you knew the pros and cons of both tests.

Below are listed the pros and cons of using Cylinder Test vs. Cube Test that are used for accurate strength testing of concrete –

Pros of Cylinder Test

Cylinder-shaped specimens are very similar to vertical components of concrete structures, such as columns. This similarity is useful to accurately determine the final performance of the concrete mix in such situations.

Another advantage of using Cylinder Test for measuring compressive strength of concrete is that it is aligned with the requirements of the ASTM standards. These standards are widely accepted all over the Americas, including the US, Canada, Central and most of South America.

Cons of Cylinder Test

The only drawback of Cylinder Test for measuring compressive strength is that the height of the specimen often produces varying results, especially if there are errors during the curing and testing stages.

Pros of Cube Test

Using the Cube Test method for measuring compressive strength of concrete provides the compression machine even surfaces to apply the pressure – the bottom, top and four sides are all equal. This helps with additional accuracy in measuring the compressive strength.

Another advantage of using the Cube Test is that, as opposed to cylinder-specimens, the cube specimens are not required to be capped with plaster or sulfur. Neither is it required to grind the cylinder to achieve perfectly parallel surfaces for the machine to work. This way, Cube Test saves significant time, effort and any variability in calculation.

Besides this, cube test is ideal for testing strength of structures, such as foundations and pavements, as the short flat surfaces perfectly mimic the components of these surface structures.

Cons of Cube Test

Though the shape of cube specimens is uniform, it is not always an ideal representation of how concrete will act in vertical structures, such as columns. In addition, the Cube Test method is not acceptable in parts where ASTM is the standard, such as in North and South America.

How to choose the right test for your project?

Below are listed the factors that will help professional builders to choose the most suitable method for strength testing of concrete –

1 – Local regulations and standards

The most important aspect to determine the best-suited method to test concrete’s strength is your regional regulations and standards regarding construction. For instance, the Cylinder Test is more suited for the Americas where the ASTM standard is applicable, while you should use the Cube Test in other regions, where BS and Eurocode standards are followed, such as in the UK, Europe and major parts of Asia.

2 – Lab facilities

Another factor to determine the best-suited testing method for concrete is the equipment and expertise available in the nearest testing lab. Usually, laboratories in North America are equipped for Cylinder Test, while in other regions of the world, you would find testing laboratories that are designed to perform Cube Tests.

In addition, you can also provide the highest level of compressive strength to concrete mix by adding concrete hardener.

Conclusion

Compressive strength testing of concrete is extremely crucial to ensure longer life and safety of structures. The two tests – Cylinder and Cube – are both used to measure the maximum load-bearing capacity of concrete mixes.

Though the two are mostly used in different parts of the world, the main aim is to determine whether the concrete mix prepared at the site is suitable to undergo wear and tear without significant damage. However, to ensure optimal strength of concrete buildings, you should always add the best-quality concrete hardener from Sakshi Chem Sciences Pvt. Ltd.

FAQS

Why compressive strength test of concrete is important?

The compressive strength test of concrete is important as it allows construction professionals to predict the properties and characteristics of concrete components. This testing helps determine whether the concrete component is strong enough for its intended use.

Which test method is more accurate?

Both test methods – Cylinder and Cube – are accurate, depending on their context and accepted areas. The regionally-accepted standards, type of construction project and its specific requirements will determine the best-suited test.

Can I use both tests on the same project?

Yes, there are situations where construction projects can benefits from both types of tests, but for different components of the structure.

What is compressive strength of commonly used concrete?

The compressive strength of commonly used concrete varies between 2200 psi (15 MPa) and 4400 psi (30 MPa). This strength level rises with commercial and industrial construction requirements. The best results are gained by using top-grade concrete hardener in the construction material.

What should I consider when choosing a test?

You should take into account the structural components, regional quality standards, and availability of equipment and expertise at local testing lab for choosing a concrete compression test.

What is compressive strength after 7 days and 14 days?

Compressive strength of concrete after 7 days is normally around 65%, and reaches up to 90% after 14 days. Adding a reliable concrete hardener can ensure early strength gain and add durability to the concrete structure.

Which test is most suitable for concrete strength?

The concrete cube test and concrete cylinder test, are both suitable for testing concrete strength, depending on your regional standards and regulations.

What is the size of concrete cubes used for testing?

Depending on the size of aggregates being used, the specimen size for cube test can be either 10cm x 10cm x 10cm, or 15cm x 15cm x 15cm.

Which machine is used for concrete strength test?

The compression testing machine is used for testing the compressive strength of concrete.

What is the rate of loading on compressive strength testing machine?

For accurate results, the load should be gradually applied at 140 kg/cm² per minute, till specimen breaks.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.