Concrete has a rightful place as the backbone of modern construction, and the movement of concrete from the mixer to the desired location is critical at any project.

Pumping of concrete redefined the way concrete placement was done, with speed and safety prevailing over manual chores such as pouring or crane lifting.

In order to pump concrete successfully, however, several points need to be taken into consideration for smooth operation and longer lifespan of the pump.

In this blog, we will discuss five important pumping Concrete basics that will guide you in making wise decisions and better performances.

Table of Contents

1. Choosing the Right Concrete Pump for the Job

Choosing the right concrete pump is crucial for a smooth, efficient concrete operation. There are two major types of pumps: boom pumps and line pumps.

Boom Pumps:

Boom pumps are usually truck-mounted, equipped with a long, extendable arm (the boom) that allows for nice elevations to be pumped accurately and efficiently into usually hard-to-access areas.

As such, boom pumps are used mainly for larger jobs that involve large-scale concrete placement, such as in the building of high-rise buildings or commercial projects or in applications where large high-volume and precise placement of concrete is required.

Line Pumps:

Line pumps are, however, are much more portable versatile pumps. In this photo, line pumps mounted on trailer-mounted or small trucks Ottawa pump concrete to desired locations using flexible hoses.

These pumps are usually old by nature and work best in smaller projects such as residential foundations, driveways, or sidewalks that do not require high placement(distance and height).

The right pump will allow you to ensure the effective enabling of the delivery of the concrete into the site resulting in huge savings on labor and time. Always look into the scope and requirements of the job before making your decision.

2. Concrete Mix and Its Impact on Pumping Concrete

There are different concrete mixes for pumping concrete. The strength of the flow of concrete through the pump and pipeline will depend on its consistency, the water-to-cement ratio, and the aggregate size.

Water reduction through cement ratios should also be ideal; that is to say, they should be fluid enough to flow through the pump but not watery enough to diminish the final structural strength.

Aggregate could possibly be too large and cause a blockage in the pump or pipes. It must remain within its recommended limits for the pump in use.

Additionally, adding some additives like plasticizers can increase the workability of the mix, thus making it easier to pump.

However, there’s a very short list of places that a concrete pump ends up accidentally… the only ones you will see on any job site are induced through the slump that is rendered from that mixture while climbing up and down a cylinder, usually between 3 and 5 inches apart.

Either side of that amount will invite serious difficulties during the pour and seriously compromise the structural integrity of the concrete.

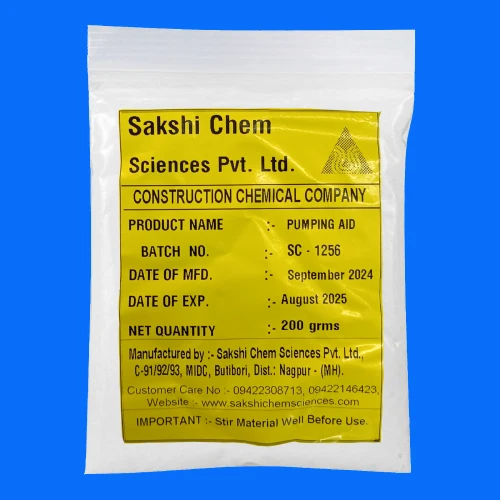

A Concrete Pipeline Primer Powder increases the hydraulic performance of thicker and stickier concrete passing through the pipeline. The powder acts by reducing the friction that enables the mix to flow through easily and avoids blockages.

3. Pipeline Set-Up and Maintenance

The pipeline set-up and its upkeep contribute essentially to an uninterrupted flow during the concrete pouring process. Either would cause stuck-up pipes, leaking, or pump damage.

Pipeline Setup and Maintenance Notes:

Keep Bends to the Minimum: Try to keep the pipe as straight as you can to reduce friction. Curvature makes resistance to its flow; thus, it will slow down the flow of concrete causing blockage.

Right Joins: Make sure to check all hoses and pipes are joined thoroughly to avoid leaking, disturbing the concrete flow, and causing accidents.

Hose Length: The longer the hose, the higher the pressure required to pump the concrete. Utilize appropriate lengths to prevent the pump from overloading.

Guides on Maintenance:

Cleanliness: After use, clean the pump and pipeline properly to remove last bits of concrete. Any concrete remaining in the pipes may harden and result in blockages that make it impossible to reuse the pump.

Inspect Hose: Look for broken spots on the hoses frequently. Hoses that are damaged present a skeletal form leading to leaking, hence accidents.

On-site application of Concrete Pipeline Primer Powder also provides lubrication for the pipelines, resulting in ease of flow and wear checks in mechanical systems. One will notice moderate familiarity with downtime, not as costly repairs for repair and maintenance probably.

4. Site Conditions and Obstructions

The constraints on the ability to pump concrete also rely on background conditions. Among others, terrains, the type of access to the site, and other obstructions directly alter how smoothly or not the process of pumping goes.

Site Access:

Confined Spaces: For confined or narrow spaces, it could be prudent to accomplish more through a line pump to offer great mobility in tighter sites.

Lifting Concrete: If concrete were being pumped to lift several stories, most likely, a boom pump would be a better option, owing to its outreach and flexibility.

Obstructions:

The presence of obstacles will be common on a construction site: these include buildings, trees, and power lines, which come together to systematically ensure pump obstruction.

Planning the pipeline arrangement to leave a reasonable distance from such obstacles is key to ensuring a smooth and straightforward process of work.

With careful investigation into site layout and possible access control exercises, you will be able to determine the most appropriate and fitting pump type and pipeline configuration to avert potential inconveniences.

5. Safety Measures and Risk Management

Timely concrete pumping requires high-pressure equipment that will require a large volume of concrete, presenting great safety hazards if not effectively managed.

Furthermore, it is imperative to observe safety during all stages of the concrete pumping process to protect workers from any incident.

Safety Measures:

Protective Equipment: PPE, in the forms of gloves, hard hats, eye protection, and steel-toed boots, must always be worn to protect against concrete splashes and other safety hazards.

Pressure Monitoring: The pressure in the pipeline and pump must always be monitored. Excessive pressure will rupture hoses and pipes. Use pressure-relief valves to avoid over-pressurization.

Training: Ensure that the operators are trained on the proper, safe use of the equipment. They, of course, should be able to manage the pump in an emergency.

Clear Communication: Use a clear communication line between the pump operator and the rest of the crew working on-site to allow for the smooth running of the work and avoid accidents.

Implementing these safety protocols efficiently contributes to safe pumping throughout the entire concrete process for the equipment and the workforce alike.

Conclusion

Pumping concrete is one of the most efficient ways to lay concrete precisely and efficiently in various construction situations.

Yet, for it to be successful, certain considerations must be given, including selecting the right pump, correct concrete mix, orientation, and maintenance of the line, site conditions, and safeguarding workers.

With appropriate attention paid to these stages, smooth concrete placement can be ensured, reducing downtime and elevating project quality.

Finding such products as concrete pipeline primer powder can improve the overall efficiency in pumping by greatly reducing friction and stopping accidental blockages, hence prolonging the life span of specific equipment.

Concrete pumping is a very straightforward and reliable solution that can work for you in accordance with the preparations being made and the care taken.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.