Description

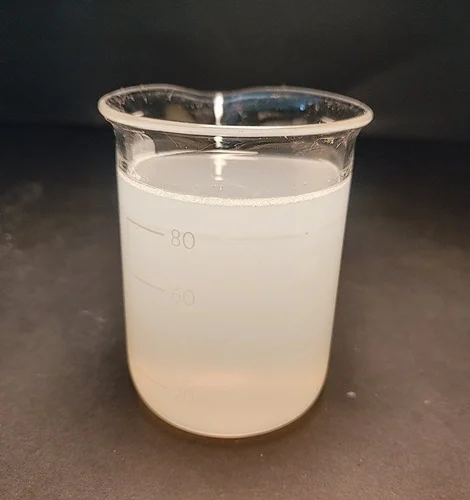

ADDAGE PLAST ESN is an advanced naphthalene based super-plasticizer to meet the rapidly developing requirements of contemporary concrete construction.

ADDAGE PLAST ESN was developed for maximum water reduction and maximum strength development through the use of innovative concrete admixtures.

The end result is the production of high-quality concrete with superior workability, early strength, and long-term structural performance.

ADDAGE PLAST ESN is also the most widely specified type of super-plasticizer in comprehensive construction applications when rapid strength development, fast removal of formwork and repeatable performance of concrete is required. Its liquid form allows for easy and consistent dispersion, making it ideal for both commercial and large-scale construction use.

Key Features

Delivering substantial water-reducing performance, but still allowing the concrete to work as intended. ADDAGE PLAST ESN achieves this via efficient dispersion of cement using naphthalene-based chemistry, resulting in enhanced flow and reduced water requirement.

The product accelerates early strength development, which allows for quicker removal of moulds and formwork. In addition, ADDAGE PLAST ESN contributes to the final compressive strength of the concrete by minimising porosity and improving the internal structure after setting.

ADDAGE PLAST ESN is designed for consistent results, reduced segregation, and consistency throughout different job site conditions.

Technical Specifications

- Brand: Addage

- Form: Liquid

- Uses: Construction

- Packaging Sizes: 60 Kg & 250 Kg

- Packaging Type: Can, Barrel

- Minimum Order Quantity: 60 Kg

Recommended Applications

ADDAGE PLAST ESN is suitable for a wide range of concrete applications, especially where strength, speed, and efficiency are required. Typical uses include:

- Structural concrete works

- Ready-mix and site-mixed concrete

- Precast concrete elements

- Foundations, columns, beams, and slabs

- Projects requiring early strength gain

- Construction requiring quick shuttering or mould removal

Its versatility makes it an ideal solution for residential, commercial, and industrial construction projects.

Dosage Guidelines

The amount of ADDAGE PLAST ESN you will need to add to your concrete based on the type of cement used, how you plan to mix it, the temperature of your surrounding environment, and what performance level you want from your concrete.

Usually, ADDAGE PLAST ESN is added to the batch when making your concrete, and should be properly mixed so that it is evenly distributed in the finished product.

When using ADDAGE PLAST ESN in the recommended amounts, you can reduce your overall water content by approximately 20-30%, and will still have good workability and strength in your concrete.

Mix trials are recommended to determine the best dosage for your specific site conditions and desired performance. It is always important to follow the technical recommendations provided by Addage for the best results.

Benefits of Using ADDAGE PLAST ESN

- High water reduction (20-30%)

- Better workability and flow when working with concrete

- Get strength within the first few hours after pouring your concrete

- Get greater compressive strength after your concrete gains its full cure

- Have the ability to remove forms and shutters faster

- Reduce the amount of porosity in your concrete for added durability

- Improve the overall uniformity of the concrete throughout the entire batch

- Decrease the amount of segregation and bleeding within the concrete mix

Adding ADDAGE PLAST ESN to your mix will allow contractors to achieve faster completion times while also providing a lasting and durable structure.

Packing

ADDAGE PLAST ESN is offered in 60 kg cans and 250 kg drums, which allows for flexibility in small and large construction jobs. The cans and drums are made from robust materials allow for secure and safe transportation and storing on-site.

Storage Requirements & Shelf-Life

Store ADDAGE PLAST ESN in a cool dry location that is not in direct sunlight and not exposed to extreme temperatures. Store the container sealed when not in use; this will prevent it from getting contaminated or losing products due to evaporation.

If ADDAGE PLAST ESN is stored under the recommended conditions, it will continue to work as intended throughout the shelf life as specified by the manufacturer.

Safety

Standard safety practices must be in place while handling and applying ADDAGE PLAST ESN. Protective gloves should be worn during application, and avoid excessive skin contact.

If there is contact with eyes or skin, wash with water. KEEP OUT OF REACH OF CHILDREN. No product should be ingested, and follow all safety protocols for the job site during application.