Concrete pumping is an indispensable service for many construction projects-whether residential, commercial, or industrial. It is one useful and fast way of delivering concrete to difficult-to-access points, ensuring that projects run smoothly and are on time.

However, just like any other part of the construction process, this also requires skillful commitment to detail. Small errors can lead to complications like delays, safety hazards, and additional costs.

Table of Contents

In the rest of the blog, we will put forth five common mistakes in concrete pumping and provide some tips for any concrete pumping service provider to avoid these.

Insufficient Attention to Site Assessment Before Pumping

Before any concrete pumping work, the pump operator is expected to assess the site to know if a pump can effectively and safely reach its destination.

One of the common mistakes in concrete pumping made by concrete pumping services is the failure to evaluate a site for access points and any obstruction or hazards in the way such as sloped grounds or unlevel surfaces.

How to Avoid this Mistake:

Take a trip around the construction site before pumping any concrete and use this opportunity to speak with the pump operator. Identify all possible obstacles-blocks like trees, buildings, or rough ground-that could obstruct access to the pouring position.

Also, check for lines across such sites that could potentially become life-threatening if the boom gets too close or touches one.

For line pumps, think about the path that hoses of the pump will take whilst activity is ongoing. Allow for enough space between hose layouts, with no vehicles, workers, or other materials obstructing this space.

When a boom pump feeds concrete into the area, there should be sufficient vertical and horizontal space above and around it for the boom to extend.

Using the Incorrect Pump Type for the Job

Every construction job is unique, and one of the most common mistakes that occur with concrete pumping involves using an unsuitable pump type for that job. Whether it is a boom pump or a line pump, the wrong pump makes for undesired inefficiencies, project delays, and even safety issues.

A boom pump for a small residential project may well seem like overkill while, should it be a line pump for a high-rise building, project slowdowns and trouble in raising might result.

How to Avoid this Mistake:

Planning is the key to this mistake’s avoidance. Before choosing a pump, assess the scale and requirements for your project.

If you are gearing up for a key project in a large scale that will require high concrete demands and which may be hard to reach, the boom pump is your best bet. Line pumps, meanwhile, will allow you to deliver concrete just as effectively and at a much-reduced cost for smaller pours.

Remembering Proper Maintenance of the Concrete Pump

Concrete pumps are advanced machines that require proper maintenance to be up and running. A large array of problems concerning concrete pumping arises from poorly maintained pumps: clogged hoses, defective parts, and inefficient pumping that stalls the project and increases your costs.

How to Avoid this Mistake:

Inspect before the usage of the pump to ensure it is never under any kind of fault. The fluids used should be at the correct levels and the pump cleaned, with every part in working order. Some companies perform pre-pour inspections of their pumps; it is wise to take full advantage of these services.

Underestimating Worker Requirements or Undercutting Training on Their Parts

Concrete pumping isn’t just about the machinery; it also demands personnel skilled enough to manage the hoses, guarantee safety, and see to concrete placement.

One of the mistakes common in the construction team is undermining workers’ needs or not providing enough training. Inadequate handling of hoses, spilling of concrete, and risk to the safety of all concerned may also arise because of such situations.

How to Avoid this Mistake:

It is crucial that enough skilled workers are on-site to efficiently supervise the concrete pump and hoses. For larger projects, a full crew trained to operate and monitor the equipment is imperative.

The crew should be trained on the safe handling of concrete hoses and aware of how to guide the flow of concrete to prevent blockages and spillages.

Ignoring Pressure and Flow of the Pumped Concrete

Another error is typically to overlook the flow and pressure of the concrete while being pumped. Too high pressure might damage the pump or cause rupturing of the hoses.

On the contrary, though, if the pressure is low, it results in an inconsistent pour and placement of the concrete, which might also lead to grouting inside the pipes. Both may cause project delays and heightened contracting costs.

How to Avoid this Mistake:

Always keep monitoring the concrete flow and pressure during the pouring. Many of the innovative modern concrete pumps have a monitoring system for pressure and flow irregularities.

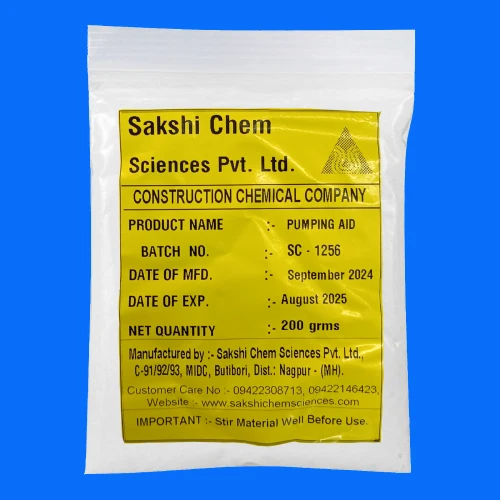

The operator must remain aware and check these monitors regularly. Use a pumping aid to improve the flow of the concrete. There are several pumping aid available in the market choose according to your requirements.

Conclusion

Concrete pumping is one of the fundamental tenets of contemporary construction, but just like any other job, it also works well when planning, preparation, and execution are involved. These common errors mentioned will ensure that the project goes on smoothly, safely, and on time.

Regardless of whether you are using a line pump or a boom pump, be sure to evaluate the site, choose the right equipment, maintain the pump, properly train your crew, and monitor the flow and pressure.

Sagar Telrandhe is a Construction Engineer with a B.Tech in Construction Engineering & Management. Passionate about infrastructure development, project planning, and sustainable construction, he specializes in modern construction techniques, project execution, and quality management, contributing to efficient and innovative building.